Custom Linear Guides Parts CNC Machining for Robotics Industry

- Machining for complex guide rail and carriage geometries

- Tight tolerances up to ±0.0005 in

- Precision milling, grinding & surface hardening

- Support for rapid prototyping and full-scale production

- ISO 9001-certified robotics manufacturing

Why Robotics Companies

Choose Zintilon

Increased Productivity

Engineers get time back by not dealing with immature supply chains or lack of supply chain staffing in their company and get parts fast.

10x Tighter Tolerances

Zintilon can machine parts with tolerances as tight as+/ - 0.0001 in -10x greater precision compared to other leading services.

World Class Quality

Zintilon provides medical parts for leading aerospace enterprises, verified to be compliant with ISO9001 quality standard by a certified registrar.

From Prototyping to Mass Production

Prototype Custom Linear Guides

Key Point

- Creating Prototypes Quickly and Accurately

- Tight tolerances (±0.0005 in)

- Test design, material, and motion quality early

EVT – Engineering Validation Test

Key Point

- Validate prototype functionality

- Rapid design iterations

- Ensure readiness for production

DVT – Design Validation Test

Key Point

- Confirm design integrity and straightness

- Test multiple materials and configurations

- Ensure production-ready performance

PVT – Production Validation Test

Key Point

- Test large-scale production capability

- Detect and fix process issues early

- Ensure consistent part quality

Mass Production

Key Point

- Steady, high-volume production

- Fast turnaround with high standards on quality

- All Industrial-Grade quality with Precision Machining

Simplified Sourcing for

Robotics Industry

Explore Robotics Components

Discover our full range of precision CNC machined robotics components, designed for strength, stability, and seamless motion. Explore parts for robotic arms, joints, actuators, frames, and end effectors, all crafted to ensure high accuracy, repeatability, and performance in modern automation and robotics systems.

- Base Plates

- Custom Arm

- High-Accuracy Joints

- Precision Gears

- Custom Gearbox

- Precision Bearings

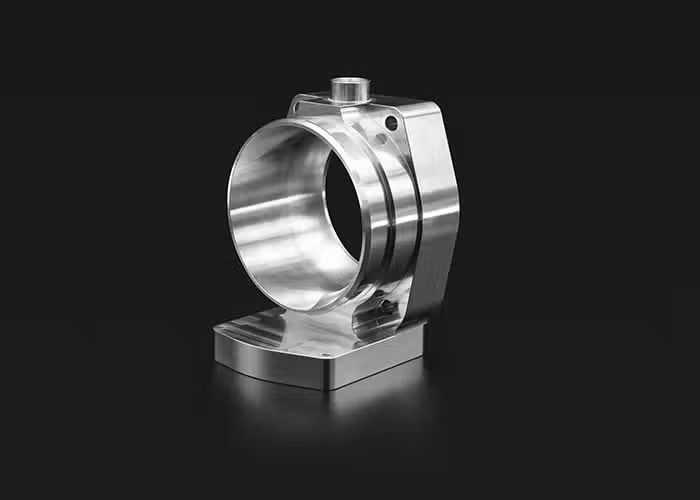

- Custom Bearing Housings

- Precision Shafts

- Custom Spindles

- Precision Sensors

- Custom Sensor Housings

- Precision End Effectors

- Custom Grippers

- Precision Frames

- Custom Structural

- Precision Brackets

- Custom Mounts

- Precision Wheels

- Custom Tracks

- Precision Gear Racks

- Precision Actuators

- Custom Valve

- Precision Housings

- Custom Cover

Robotics Custom Linear Guides Machining Capabilities

We create, precision surface grinding, profile grinding, lapping and induction hardening for perfect running surfaces and dimensional stability. straightness measurement & CMM, and verification, hardening, Each part of custom rails fabricated from bearing steel (52100, SUJ2), tool steel (D2, M2), stainless (440C, 17-4 PH) and aluminum (6061-T6, 7075-T6) all of which provides exceptional hardness wear after continuous motion in an industrial environments.

Aerospace

Materials & Finishes

Specialist Industries

Materials for Custom Linear Guides Components

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

FAQs: Custom Linear Guides for Robotics Applications

Anodizing (Type II and Type III)

Passivation for corrosion resistance

Precision polishing for aerodynamic surfaces

Custom protective coatings and thermal barriers