Surface Finishing

Careful surface finishing helps to appearance and performance. We offer diverse surface finishes for a great variety of materials.

Our Surface Finishing Specifications

As machined, parts have minor visible tool marks and a surface roughness (Ra) of 1.6-3.2 µm.

Bead blasting is a cold treatment process used to remove old paint films with a thickness of not less than 2mm. It is widely used to improve the mechanical strength of parts, as well as wear resistance, fatigue resistance and corrosion resistance.

Sand blasting is to make the surface of parts for uniform matte treatment, according to the requirements of different sizes of sand can be sprayed, such as aluminum can spray #80-220 fine sand.

Painting can make the monotonous product look more beautiful after being sprayed with various colors, and at the same time, it can prolong the life and service life of the product because of an extra layer of protection.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Plating is a process that is often used in CNC machining to add a protective or decorative layer to the surface of a component.

The surface of the material is coated with a layer of zinc to play the role of beauty and rust prevention.

Chroming process in CNC Surface Finishing is a metal finishing process that uses a chemical bath to deposit a thin layer of chromium onto the surface of a metal object.

A layer of nickel is plated on the surface of the material to improve the corrosion resistance of the material and have excellent polishing performance.

Laser engraving uses laser to engraving the logo or character logo you need onto your component.

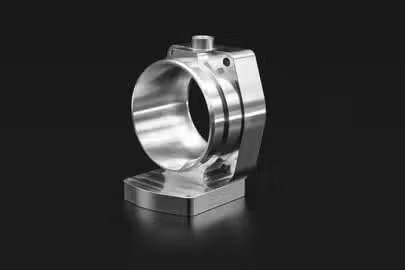

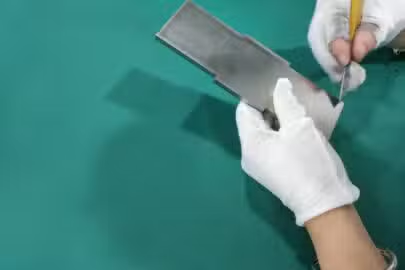

The result of brushing is a unidirectional satin finish that is achieved by polishing the metal with grit.

Smooth polishing is to removes the machining marks from the surface of the workpiece, but there is no mirror effect.

Mirror polishing is a surface finishing process that can create a highly reflective, mirror-like finish on metal parts.

By silk screen printing, the ink is adhered to the products surface allowing it to be printed in a variety of colors at the same time, resulting rich and gorgeous effect.

E-coating is a CNC Surface Finishing process that uses electrochemical methods to deposit a protective coating onto metal parts.

Powder coating is a process used to coat metal parts with a protective and decorative layer of paint. It is often used for applications such as automotive, marine, and industrial part.

The passivation process can help to extend the life of the CNC surface, which can increase the longevity of the machine.

A technology that uses a metal workpiece as an anode and performs electrolysis in a suitable electrolyte to selectively remove its rough surface and improve the surface finish.

The heat treatment methods include vacuum heat treatment, bright heat treatment, nitriding, nitriding, QPQ and blackening. The hardness range of heat treatment is 40-60 HRC.

Alodine is a chemical surface finishing process used to produce a protective coating on aluminum and its alloys. It is also known as chemical film, or chromate conversion.

A more environmentally friendly and efficient alternative to preparing chromate conversion using safer raw materials. The chromate conversion process can be used for oxidation, corrosion protection and modification of metal surfaces to improve the durability and performance of parts

Black oxide provides corrosion protection, improved electrical conductivity, and improved wear resistance, making it a popular choice for CNC surface finishing.

Surface Finishing Introduce

Products vary with weight, appearance and function of the product, which also poses new challenges to our surface finishing technology. Our company has professional experience and equipment in surface finishing. Click below to view the available materials for each surface finishing.

Gallery

Voice of Customers

Service Applications

one

More Details