How Zintilon Guarantees Superior Quality

Consistent Materials

We attach great importance to materials throughout the production. Our sales will confirm the material, tolerance, quantity and other requirements with the customer while quoting. Our purchaser ensures that the material type and characteristics are as required by the customer. Engineers and machine operators conduct visual and 3-dimensional inspections of the materials to gurantee the materials consistency.

Self-owned manufacturing equipement

Unlike the trade platform enterprises, our company has been an integrated industry and trade enterprise focusing on custom precision prototyping and parts since our establishment. We prioritize high-precision equipment and talents. In addition to the company's own 22,000 square meters of plant, we also introduced a number of well-vetted suppliers to ensure that the accuracy of customer parts and quality consistency.

Skilled engineer

We have excellent experienced engineers, some of whom have been in the metal facturing for over 20 years, which means we are a company with a strong technical DNA. We continue to bring in experienced technical talents, from production operators, programming, engineering to quality control staff, ensuring that your parts are rigorously inspected for high quality.

High-quality Machining

Technology and talents are our core competitiveness. Our experienced engineers will start professional DFW analysis accoding to the customer's drawings and requirements, including techniques, machines, cutting tools, precautions, etc. We will arrange engineers and sales to communicate with you by video conference when necessary for large size, parts with deep holes, taps, non-standardized threads, or thin-walled parts with curved-shape surfaces. We strictly follow the ISO9001 standard to ensure the parts quality meets the customer's requirements.

Multiple inspection process

We pay great attention to customer satisfaction. In order to ensure that the quality meets customers' expectations, we have introduced a large number of advanced machining and quality inspection equipment, such as Hermle 5-axis, zeiss CMM, etc. In addition, we have also introduced elite and experienced talents, including operators, programmers, engineers, quality inspectors, etc. to ensure that we have the ability to bring customers' designs into the real world in terms of materials, processing, testing, surface finishes and more.

Meticulous Quality Assurance Measures for Metal Manufacturing

01Before the production

We will provide material report from suppliers of raw materials on customers’ request. Usually, we will use spectrometer and other equipment to detect the composition of the product before the dimensional inspection. And therefore, we gurantee that the strength, hardness can meet the customers' demands.

02During the production

03Before the delivery

Cutting-edge Manufacturing Equipment

Various Inspection Facilities

We use a variety of equipment and tools, including zeiss CMM, to inspect the appearance, function, and performance of the product, ensuring meticulous inspection to deliver parts that meet precision and high reliability.

Quality Reports

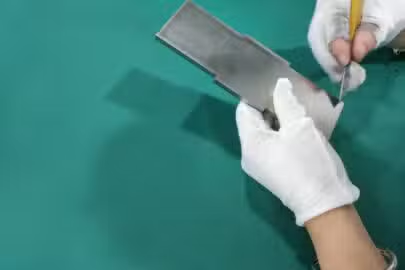

Visual inspection

Our staff will check the appearance including color, materials, etc. physical properties according to their experience.

Materials Certification

We provide materials certification like RoHS to verify whether the parts meet our customers‘ demands if in need.

Dimensional Inspection

Vernier calipers, micro calipers and height gauges are used to check simple structure parts, while zeiss CMM inspection is used for complex shaped parts.

Performance Inspection

For parts with holes and threads, we will check whether the assembly is suitable.

Bello Inspection

Test the adhesion of the test object after it has been painted.

First Article Inspection

We will tell our customers all the inspection results and procedure in the final stage of inspection.

Salt spray Inspection

Use the artificially simulated salt spray environmental conditions created by the salt spray test equipment to evaluate the corrosion resistance of products or metal materials.

Reliability Inspection

Find out the problems existing in the parts in terms of raw materials, structure, technology, environmental adaptability, etc., and improve them after repeated tests and improvements.

Film thickness Inspection

We use thickness meter to check the thickness of the metal or non-metal covering layer on the substrate, such as the Cu/Ni/Au layer in the PCB board process, the Ni/Cr covering layer on the alloy, etc.

Gallery of industrial mechanical parts

Quick response to our customers

We are committed to delivering high precision parts or prototype to you. In case that our parts prototype fails to satisfy your needs, please do not hesitate to contact with us, we will find a re-do or refund solution to any quality issue within 3 month of receiving your goods once your project meets the following conditions. We will give you feedback within 1-3 business day after you tell us the quality issue within 7 business days of your received delivery.

Conditions for Rework

If you come across any problems with your prototyping ot parts, just free free to contact with us. We will check the design and your received products for the inconsistency and redo your products as soon as possible if the your samples has the follow problems.

- Unacceptable products defects like tolerance, materials.

- 2D and 3D drawings are inconsistent without confirming with clients before delivery

- Other

Conditions for Refund

We will quickly response to your refund request if we find our product issue can not be solved.

- Product fails to meet the customer’s requirements about material, tolerance, quality, etc.

- Other

FAQs

The tolenrance range of sheet metal fabricated parts is ±0.2-0.3 mm.

We have strict quality control standards to ensure the quality of our low-volume production. Firstly, we check incoming materials to ensure material quality. Secondly, we inspect and test the production process to ensure that you get quality parts that exceed expectations. Thirdly, we can provide certificates of compliance for all materials.

Digital Manufacturing Resources

Let's Start A New Project Today