The alodine process forms an oxide film on the surface of the metal, which provides corrosion protection, improves adhesion for painting, and provides electrical insulation.

Alodine is applied using an electrochemical process and produces a thin, uniform coat that adheres to the substrate and helps protect against damage from UV rays, salt, and other environmental factors.

Available Materials

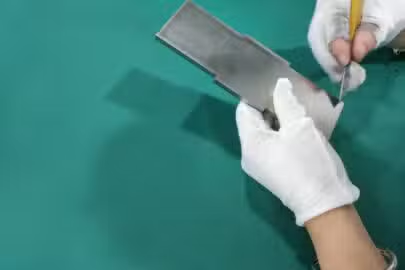

Aluminum

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Price

$ $ $

Lead Time

< 10 days

Tolerances

±0.125mm (±0.005″)

Max part size

Min part size

Design Considerations

- Select the right Alodine process for the application. Depending on the material, environment, corrosion resistance and appearance requirements, the type of Alodine process should be selected.

- Ensure proper setup of the Alodine process. Proper setup is important to ensure that the parts are processed correctly. This includes making sure that the CNC machines are properly calibrated, the chemicals used in the Alodine process are properly mixed and applied at the right temperature and pressure, and that the parts are adequately rinsed and dried.

- Monitor the process for consistency. It is important to make sure that the Alodine process is consistently producing the desired results. This includes regularly testing for thickness and uniformity of coating.

- Consider the safety of the workers. The chemicals used in the Alodine process can be hazardous, so workers must be appropriately trained and provided with the proper protective equipment.

Digital Manufacturing Resources

Let's Start A New Project Today