The thickness of anodizing is graded, and the grade specifications depend on the application. The range that ZTL can do is from 3-30 microns.

The oxidized product is denser, stronger, thicker, non-conductive, and has a wider range of applications.

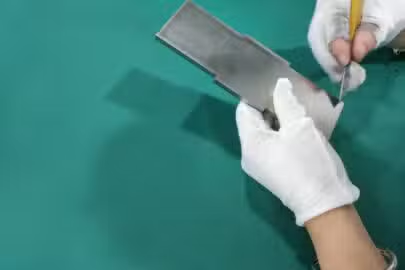

Materials For Anodizing

Aluminum

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Price

$ $ $

Lead Time

< 10 days

Tolerances

±0.125mm (±0.005″)

Max part size

Min part size

Design Considerations

- Anodizing has insulative properties, so anodized parts have poor electrical conductivity.

- All edges and corners on the workpiece should be rounded with a radius of no less than 0.5 mm, and no burrs are allowed. This prevents local overheating and burning of the workpiece caused by the current concentration.

- Workpieces with rough surfaces can become smoother after hard anodic oxidation treatment. However, workpieces already possessing an extremely smooth finish will lose some smoothness.

- In the process of hard anodizing, the workpiece must bear high voltage and current. Special fixtures must, therefore, be designed to keep the workpiece in good conductive contact. It will otherwise break down or burn the contact parts of the workpiece.

Digital Manufacturing Resources

Let's Start A New Project Today