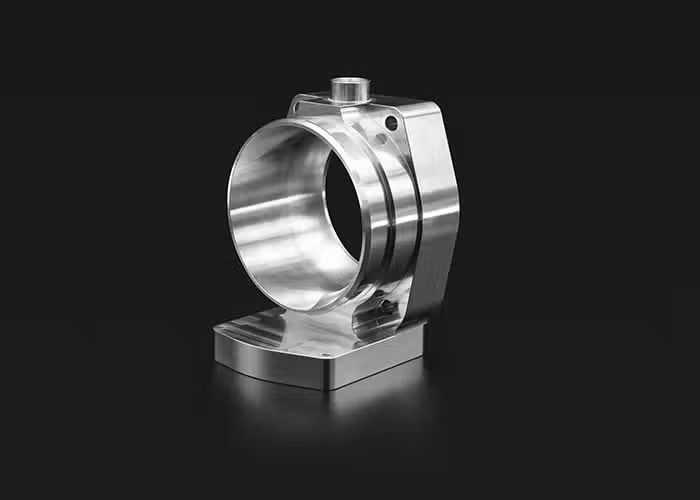

E-coating is a great choice for CNC metal parts, it is a green, cost-effective and efficient alternative to traditional metal finishing processes. Because it provides a high-quality finish, is very durable, and is environmentally friendly.

Available Materials For E-coating

Aluminum

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Zinc

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Titanium

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Iron

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Steel

Steel is a strong, versatile, and durable alloy of iron and carbon. Its applications range from construction materials and structural components to automotive and aerospace components.

Steel is strong and durable High tensile strength Corrosion resistance Heat and fire resistance Easily molded and formed.

Stainless steel

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

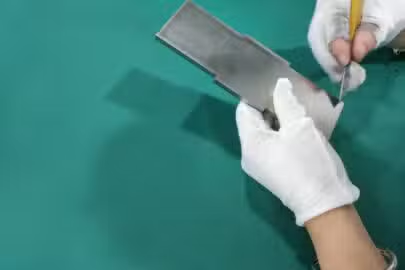

Design Considerations

- Pay attention to whether the material is suitable for electrophoresis. Some materials are not capable of using the post-processing properties of electrophoresis.

- Pay attention to the time of the electrophoresis. The final product will be different if the electrophoresis is complete and incomplete.

- Electrophoresis can improve the usability of the product and enhance the appearance, so it can be appropriate to add post-electrophoresis treatment to the product.