The ability to be heat treated and provide corrosion resistance qualities is one advantage of employing steel alloys.

Steel has a broad range of possible uses for CNC milling, including medical equipment, electronics hardware, and other items requiring more formability and weldability.

Steel is sensitive to temperature changes Susceptible to fatigue and cracking higher cost of production.

Available Finishings

As machined, parts have minor visible tool marks and a surface roughness (Ra) of 1.6-3.2 µm.

Sand blasting is to make the surface of parts for uniform matte treatment, according to the requirements of different sizes of sand can be sprayed, such as aluminum can spray #80-220 fine sand.

Plating is a process that is often used in CNC machining to add a protective or decorative layer to the surface of a component.

The surface of the material is coated with a layer of zinc to play the role of beauty and rust prevention.

A layer of nickel is plated on the surface of the material to improve the corrosion resistance of the material and have excellent polishing performance.

Laser engraving uses laser to engraving the logo or character logo you need onto your component.

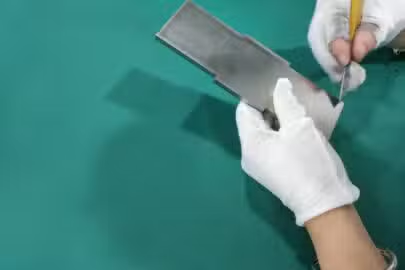

The result of brushing is a unidirectional satin finish that is achieved by polishing the metal with grit.

By silk screen printing, the ink is adhered to the products surface allowing it to be printed in a variety of colors at the same time, resulting rich and gorgeous effect.

E-coating is a CNC Surface Finishing process that uses electrochemical methods to deposit a protective coating onto metal parts.

Powder coating is a process used to coat metal parts with a protective and decorative layer of paint. It is often used for applications such as automotive, marine, and industrial part.

The heat treatment methods include vacuum heat treatment, bright heat treatment, nitriding, nitriding, QPQ and blackening. The hardness range of heat treatment is 40-60 HRC.

The passivation process can help to extend the life of the CNC surface, which can increase the longevity of the machine.

Smooth polishing is to removes the machining marks from the surface of the workpiece, but there is no mirror effect.

Mirror polishing is a surface finishing process that can create a highly reflective, mirror-like finish on metal parts.