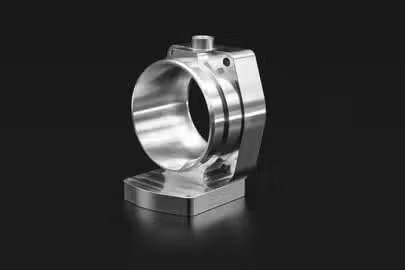

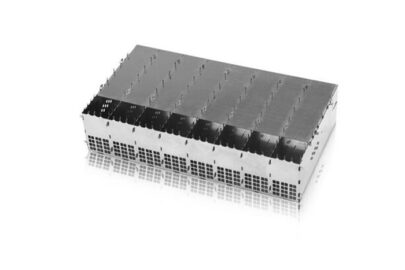

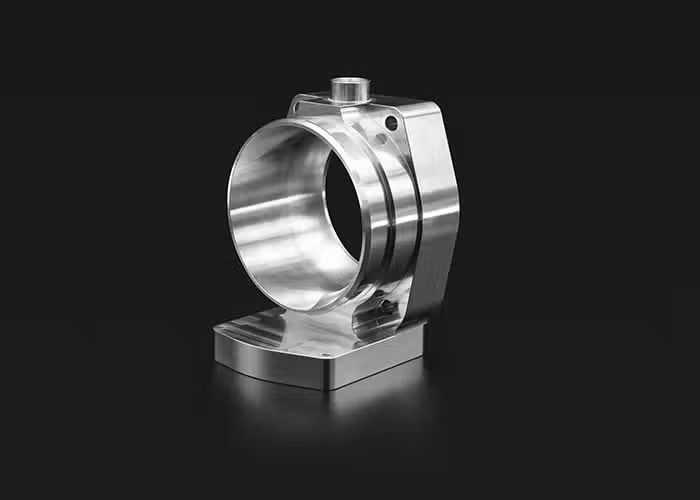

We offer a complete stainless steel CNC machining service and can produce complex stainless steel parts with 11 different types of stainless steel.

Stainless steel is a fully recyclable alloy composed of iron, carbon and between 11-18% chromium. This hardens and toughens the steel, increasing its corrosion resistance at high temperatures and preventing rust.

Stainless steel is very strong, resistant to corrosion, easy to clean and sterilize—especially useful for medical equipment—resistant to extreme temperatures and great for welding.

Our CNC services enable you to create custom stainless steel parts for many applications across industries such as energy, medical technology, agriculture, industrial automation, machinery, robotics and construction.

Steel Finishing Options

As machined, parts have minor visible tool marks and a surface roughness (Ra) of 1.6-3.2 µm.

Sand blasting is to make the surface of parts for uniform matte treatment, according to the requirements of different sizes of sand can be sprayed, such as aluminum can spray #80-220 fine sand.

Plating is a process that is often used in CNC machining to add a protective or decorative layer to the surface of a component.

A layer of nickel is plated on the surface of the material to improve the corrosion resistance of the material and have excellent polishing performance.

Laser engraving uses laser to engraving the logo or character logo you need onto your component.

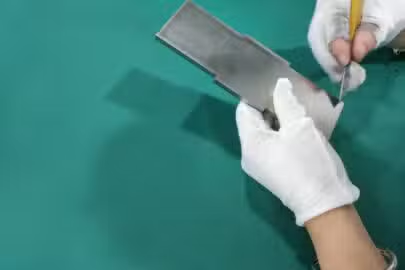

The result of brushing is a unidirectional satin finish that is achieved by polishing the metal with grit.

By silk screen printing, the ink is adhered to the products surface allowing it to be printed in a variety of colors at the same time, resulting rich and gorgeous effect.

E-coating is a CNC Surface Finishing process that uses electrochemical methods to deposit a protective coating onto metal parts.

Powder coating is a process used to coat metal parts with a protective and decorative layer of paint. It is often used for applications such as automotive, marine, and industrial part.

Smooth polishing is to removes the machining marks from the surface of the workpiece, but there is no mirror effect.

Mirror polishing is a surface finishing process that can create a highly reflective, mirror-like finish on metal parts.

A technology that uses a metal workpiece as an anode and performs electrolysis in a suitable electrolyte to selectively remove its rough surface and improve the surface finish.

Black oxide provides corrosion protection, improved electrical conductivity, and improved wear resistance, making it a popular choice for CNC surface finishing.