CNC machining is a high-precision and versatile traditional manufacturing process suitable for low-volume production runs of intricate components. Manufacturers can quickly create robust parts and prototypes for particular uses with CNC machining.

CNC machining is a subtractive manufacturing process. Instead of gradually depositing material, as with additive manufacturing techniques, CNC machining works by cutting progressively away at a solid block of material to create the final part.

Material selection is critical in any manufacturing process, but engineers and product teams must be cautious when selecting materials for CNC machining. Because this process is compatible with a wide range of materials ranging from metal to fibreglass to wood, it’s easy to choose an adequate material but not ideal for the project. This article will discuss critical considerations for CNC machining material selection and provide an overview of some standard options.

Understanding Material Properties

The characteristics of the materials affect how the machining process interacts with them. Every material has a distinct set of properties that can significantly impact the machining process, the final product’s functionality, and its durability. Here are some things to note:

Hardness

Picking the suitable materials for CNC machining projects is essential. Hardness matters a lot. It means how much the material can bend or scratch without being damaged. In CNC machine work, rigid materials are often used for cutting tools because they stop wear and keep their sharp edges long. Two common ways to test how hard something is include the Brinell, Vickers, and Rockwell scales. Metals such as tool steel and carbide are hard. They are known for this, making them suitable for operations requiring exact cutting.

Toughness

The strength of a material shows how much energy it can take without breaking. In CNC machining, it’s essential to have strength. This is especially true when working with loads that move or hit things. Strong things do not break or crack easily when pressure is applied. Materials like stainless steel and titanium, mixed in alloys, are often picked because they have strong parts and are tough. This makes sure that the pieces last for a long time.

Ductility

Ductility means how much a material can bend or stretch without breaking when applying pressure. It’s better to use soft materials for projects that use CNC machining when we need complicated shapes or tricky designs. Ductility makes it easier to shape things without breaking them. Usually, bendable stuff like aluminum, copper, and special kinds of steel are used. This makes them good for many things CNC can do.

Choosing the Right Material for Your Project

Manufactuers can select the material that best suits their needs thanks to the variety of materials available for CNC machining. Before selecting machining materials for your projects, it is critical to understand the different aspects to consider. This will guarantee that your projects are successful and assist you in making well-informed decisions.

Machinability

Machinability is an essential thing. It directly affects how well the machining process works and how much money it costs. This feature includes how easy it is to cut, form, and finish a material using tools like machines. The best working ability means less wear on cutting tools, easier chip formation, and a nice surface finish. Steels that are easy to cut, aluminum mixes, and brass are famous for being good materials. They are popular options for using machines in lots of CNC applications.

Strength Requirements

We must check if our chosen material can handle pressures and weather changes because it’s very important. This means looking at tensile strength, yield strength, and maximum strength. These show how strong a material can be under different weights or stresses. Finding out what a thing does and considering things like heat, rust, or contact with strong chemicals are important parts. Metals like titanium, certain aluminum mixes, and strong steel are often picked for jobs requiring extra strength. This ensures the final product lasts long, and you can trust it.

Surface Finish Needs

The end result of the machined product depends on the surface finish and how it looks. For example, a part with a rough surface might feel more friction. This could cause it to wear out quickly and break down too soon. However, a part with a smooth surface finish will have less resistance. This means better performance and longer life. Furthermore, how something looks also depends on its surface finish. A smooth surface finish can make a part look better and more attractive to buyers.

So, it’s important to think about the surface finish needs for the finished product. Some material types are better to make a smooth finish than others. For example, metals like aluminum and brass are not hard to make smooth with machinery. On the other hand, materials like carbon fiber and fiberglass can be harder to work with when making things. Getting a nice, smooth finish might need special tools or methods.

Cost Considerations

Firstly, the cost of a material can change a lot based on what kind and how much you need. Expensive metals might be used, but plastics or mixes often give a better budget choice. Making a budget is very important. It helps you pick things you can afford and stay on track.

Secondly, the costs of CNC machining can be pricey and take a lot of time. Money and time are affected by many things. This includes the difficulty of the piece, the kind of resource used, and the machines needed. Choosing cheaper tools that still do the job can help lower the total costs of making things.

Finally, the cost of the materials chosen can affect the quality of the final product. Cheap choices may have problems or break quicker than more expensive ones. So, selecting good material and managing your money well is very important to ensure the final product lasts and meets high standards.

Common Material Options for Machining

Because any material hard enough for machining – metal or plastic – can be used for CNC manufacturing, product teams are spoiled for choice. This overview covers some of the most commonly used materials in CNC manufacturing today.

Aluminum

Aluminium is an essential material in CNC machining because it has excellent qualities. Its low density makes it very light, and its ability to not rust helps it last in different places. Also, aluminum is very strong for its weight and is used extensively in different fields.

One thing that makes aluminum special is its excellent ability to be worked on by machines. Materials like 6061 and 7075 are very easy to work with. They don’t make big pieces of waste when they are being made or worked on. This feature makes tools last longer and work better, making it a top choice for detailed and accurate machine jobs.

The several uses of aluminum are shown in different ways. In airplanes, its light weight helps to save fuel. So it’s a good choice for making parts of planes. Things people use every day are easy to work with and have a pretty look, making them good for making small parts of gadgets. Aluminum is used in many ways, like auto or big building parts. It is very useful in CNC machining for many things.

Plastics

Plastic gives CNC machine workers many choices. They can use ABS, PVC, and PEEK for easy work. These things are cheap, easy to carry, and have good strength features. They can be used in different ways.

In general, plastics have good qualities that make them easy to work with using machines. CNC machine processes can be done very accurately with little tool damage. But it’s important to think about heat sensitivity, like when working with some plastic stuff.

Plastic is often used in CNC machining, especially for quick models. It’s about saving money and being easy to work with. Plastics such as PEEK are good for making medical parts because they can work with living things. Plus, plastics can be used for electronics, and rapid prototyping that requires accuracy. The ability of plastics to change makes them a good pick for CNC machining projects with many needs.

Steel

Steel, a strong material, is famous for its strength and flexibility. This makes it a top pick in CNC machining. Different kinds of steel have different qualities, allowing customized choices to meet certain project needs. Steel is very strong, long-lasting, and easy to shape. This is why it’s often used in different businesses.

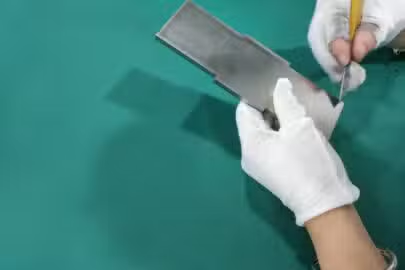

Steel is famous for being easy to work with, but some types, like free-cutting steels, are made special to make them even easier to machine. This way of making tools wears down less, which makes the process of cutting things faster and better. How easy it is to work with steel is very important when using it for cutting tools and other exact machining jobs.

In CNC machining projects, steel is often used. Heavy steel is frequently used in the auto industry to create various parts. This makes them last a long time and be safe. Steel is used in many different CNC machining jobs. In the car business, people often use strong steel to make parts. This helps them stay safe and last a long time. Tool steels, which are hard and don’t wear out easily, are liked for making sharp tools. This shows that steel is helpful in many ways for machines. Steel is very versatile, especially in the building world. It’s used for making parts of buildings, showing how important it is today.

Brass

Brass is a well-known thing used in CNC machining. People like it because of its special qualities. Made mostly of copper and zinc, brass can easily be made into different shapes. It does not rust easily and has a pretty golden color. These features make it a favorite pick for different uses, especially those needing exact work and good looks.

Brass is famous for being easy to work with machines. It makes smooth pieces and can be easily shaped during the process. This quality helps to decrease tool damage and makes machining tasks work well. Brass is excellent for detailed designs and exact parts because it’s easy to work with.

Brass is used in many ways because it can do different things. It is often used to make detailed parts, power cables, and pretty things. Brass is a popular material for making CNC machine parts because it looks nice, doesn’t rust easily, and is easy to work with.

Titanium

Titanium is a good material for CNC machines because it’s strong and lightweight. It also doesn’t rust easily and is safe to use in the body. Its unique mix of features makes it suitable for uses where strong but lightweight parts are needed.

Titanium is often considered hard to work with because it’s strong and doesn’t let heat through easily. But now, new ways of working have made it easier for people. Working with titanium requires extra care to keep the tools strong and protect the material.

Titanium is used a lot in space, medical, and car businesses. In the sky, its lightness helps save fuel and makes it good for the medical parts of our bodies. Titanium’s strength and protection against rust make it essential in parts exposed to hard conditions. This shows its ability to be useful in tough CNC machining uses.

Additional Factors to Consider

Titanium CNC machining

Here are some factors to consider before choosing the right material for your CNC machining:

Tolerances Required

Getting just the right measurements is very important in CNC machining. It greatly affects the selection of materials we use. The amount of acceptance needed for a project decides if the material is good, with some uses requiring very tight limits. Aluminum and some steel are often chosen because they have mechanical solid features that stay steady while making things. They behave in a way that can be predicted well. These materials are stable, and they give accurate results. This makes them suitable for projects that need to follow measurements exactly. It’s also important to know how a material reacts when it gets hot or cold. This is especially useful during the making, like when heat affects how things fit together just right.

Post-Machining Processes

Thinking about what happens after the machine works is essential to ensure the finished item fulfils all project needs. Different materials might need more steps or treatments to make them better or meet industries rules. After the machines finish working, these processes can include surface changes, heat treatments, putting on a cover, or more work by the machines. Choose the suitable material that matches what you’ll do after using machines on it. Consider whether it works well with specific processes and requirements for your whole project. Factories like car makers, airplane producers, and medical equipment creators often need these extra steps to meet high-quality standards. This shows how much material choice matters in the whole process of making things.

Environmental Conditions

Considering the environment when choosing materials for projects using CNC machines is essential. Different places have different problems. So, we need extraordinary things that can do well and last a long time in these places. Corrosion resistance is significant, especially in areas where parts are near water, chemicals, or bad weather. Stuff like stainless steel or rust-resistant mix is usually picked in these cases. It protects from getting worse over time.

Another essential thing to consider is keeping the temperature steady, particularly for tasks in very hot or cold situations. For these uses, the materials must be stable with heat to show good results in different temperature levels. In fields like ocean engineering, where parts often are in contact with salt water and must stop rusting, it’s essential to handle challenges from nature.

In some uses, like medical gadgets or parts in contact with people’s bodies, making things compatible with the body is very important. Things like titanium, known to work well with the body, are essential. They stop bad reactions and ensure medical parts stay safe and work right.

Conclusion

One of the most important aspects of modern industry is design for manufacturing. The development of material science has made careful material selection more and more critical for CNC machining. At Zintilon, we provide a wide range of materials, from highly sought-after metals to premium plastics, and we specialize in CNC machining services, including CNC milling and turning. Our team’s experience and 5-axis machining capabilities enable us to offer our customers unmatched quality and precision. Contact us now!We are committed to giving our clients the best possible customer service, assisting them in reaching their objectives, and cutting expenses. Our technical staff can help you select the best project materials and offer free, professional advice. We can assist you at every stage, regardless of whether you have a specific project in mind or require custom CNC machined parts. Get a quote to get started!

Read More

- What is M-Code: Definition, Function, Types and Uses – Zintilon

- What is CNC Machining? – Zintilon

- Anodized Aluminum Cost: What Factors Affect the Cost of Anodizing? – Zintilon

- An Expert Guide to Matching Materials with Your CNC Machining Projects – Zintilon

- Aluminum Die Casting vs Zinc Die Casting: A Detailed Comparison – Zintilon