The demand for stainless steel is growing by 5% annually. Various industries, including automotive, medical, and household appliances, are increasingly using stainless steel.

There are numerous types of stainless steel suitable for custom manufacturing needs. Each stainless steel type comes with unique properties like tensile strength, oxidation resistance, corrosion resistance, and melting point.

Choosing the appropriate grade of stainless steel depends on understanding the available options. To help you comprehend your choices, this article will explore common types of stainless steel and their properties. You will learn why this metal is prevalent across industries and how to use it to your advantage.

What Is Stainless Steel?

Stainless steel refers to a family of approximately 200 steel alloys known for their impressive heat and corrosion resistance properties. Steel material itself is an alloy of carbon and iron. Its maximum carbon content of 2.1%. Stainless steels incorporate alloying elements. The carbon percentage in these steels can vary from 0.03% to 1.2%.

A key feature is the elevated chromium content, with a minimum of 10.5%. The notable amount of chromium contributes to improved strength and corrosion resistance. When exposed to air, chromium in the alloy forms a passive layer through oxidation. This layer acts as a protective shield, preventing further corrosion and rendering the alloy rustproof. This mechanism ensures a clean appearance for extended periods under normal working conditions.

Stainless Steel Properties

Before we go into the various types of stainless steel available, let’s briefly discuss the properties of stainless steel that make it useful for a wide range of applications.

Mechanical Properties

Some of the mechanical properties of stainless steel include the following:

- Yield Strength: Stainless steel varies in yield strength depending on the grade. Some grades exhibit high strength and low elongation. Others have low strength and high elongation. Its yield strength compares favorably to that of carbon steels.

- Tensile Strength: Stainless steel surpasses materials like mild steel, aluminum, and brass in tensile strength. Precipitation hardening and martensitic grades exhibit the highest tensile strengths. Duplex steel, particularly, boasts a high strength/ductility ratio.

- Strength at High Temperatures: Stainless steels outperform carbon steels at elevated temperatures. They display better fire resistance due to their high strength retention factor above 500°C. They also retain stiffness better than carbon steel above 300°C.

- Ductility: Ductility varies significantly among different grades of stainless steel. Some display high ductility suitable for strenuous deep drawing processes.

- Cryogenic Resistance: Certain stainless steel grades excel in handling a broader temperature range. Austenitic steels exhibit exceptional toughness and increased tensile strength at sub-zero temperatures, expanding their applications for modern uses. However, martensitic, ferrite, and precipitation hardening grades are less effective at cryogenic temperatures.

- Work Hardening Rate: Stainless steel’s ability to increase strength through cold working processes allows for manipulation of its strength to desired levels. The same grade can be used for various applications by adjusting its strength through annealing and cold working.

- Magnetism and Electric Conductivity: Austenitic stainless steels are non-magnetic, but cold working can induce magnetic properties in some grades. However, other types inherently display magnetic properties. While stainless steel conducts electricity like all metals, its conductivity is low. In industries with high hygiene standards or exposure to corrosive or humid environments, stainless steel enclosures are employed for protection.

Chemical Properties

The unique qualities of stainless steel arise from its chemical properties.

- Oxidation Resistance: Stainless steel’s notable oxidation resistance is attributed to its chromium content. Unlike metals requiring coatings and anti-corrosion paints, stainless steel forms a new chromium oxide coat on damaged surfaces. This prevents corrosion even after the removal of the natural coating.

- Biologically Inert: Being biologically inert makes stainless steel a logical choice for medical equipment like surgical tools, screws, and plates. This property also makes it ideal for cutlery and kitchen appliances.

- Resistance to Chemicals and Organic Materials: Acid resistance varies among grades, with some capable of withstanding highly concentrated acids. Similar non-reactivity is observed with bases and organic compounds. This makes stainless steel suitable for use in chemical industries for handling, storage, and other processes.

- Additional Resistances: Stainless steel resists salt, sulfur, moisture, chloride compounds, and carbon dioxide. This enables it to endure harsh environments for extended periods compared to most other metals.

Other Properties

The essential properties extend beyond just mechanical and chemical aspects. Other valuable characteristics listed below prove advantageous for various applications.

- Recyclability: Stainless steel can be recycled to create new products, easing the environmental impact using fewer raw materials and minimizing waste. Its non-biodegradable nature prevents contamination of soil or water reservoirs.

- Easy Workability: Stainless steel is highly machinable and workable, allowing designers to craft complex shapes and products. Services like stainless steel laser cutting, CNC machining, and sheet metal bending are readily available without special equipment.

- Cleanability: Stainless steel products are easily cleaned with household non-toxic products such as soaps, detergents, or cleaning liquids. This simple cleaning process maintains a fresh appearance, prolonging the service life.

- Aesthetic Appeal: Stainless steel products boast higher luster. This makes them an ideal choice for exposed surfaces. They are available in various finishes, from bright to matte. Stainless steel can be brushed, embossed, and engraved to achieve desired aesthetic effects.

What Are the Different Types of Stainless Steel?

Though different types of stainless steel exist, they generally belong to one of five categories. But before we go into their details, here’s a table comparing the five grades of stainless steel.

| Property | Martensitic | Ferritic | Martenistic | Duplex | Precipitation-Hardening |

| Composition | High chromium and nickel | Chromium, no nickel | Chromium, higher carbon | Chromium, nickel, molybdenum, nitrogen | Chromium, nickel, precipitate-forming elements |

| Corrosion Resistance | Excellent | Superior | Less than austenitic | High | Matches austenitic |

| Mechanical Properties | Excellent ductility and toughness | Comparable to carbon steels | High mechanical strength and hardness | Increased strength with double or more yield strength | Very high strength |

| Workability/Weldability | Easily workable and weldable | Generally unsuitable for welding | Challenging due to high carbon content | Weldable and fabricable, though not as easily as austenitic | Machined and fabricated in the soft, solution-annealed condition |

| Magnetic Properties | Non-magnetic (may become slightly magnetic after cold working) | Magnetic under all conditions | Magnetic under all conditions | Magnetic under all conditions | Magnetic under all conditions |

| Heat Treatment | Hardening through cold-working, not through heat treatment | Generally annealed condition, not heat-treatable | Hardening with heat treatment | Not heat-treatable | Heat-treatable for very high strength |

| Strength | Good strength | Comparable to carbon steels | High mechanical strength | Increased strength with double yield strength | Very high strength |

| Applications | Various industrial applications, including chemical processing | Automotive applications, smaller handheld items | Handheld items, cutlery, springs, furnace components | Chemical processing, marine applications, construction | Aerospace, nuclear, chemical applications, boat shafting |

| Limitations | Limited high-temperature strength, magnetic after cold working | Poor high-temperature strength, generally unsuitable for welding | Limited ductility and resistance to cold working, challenging to weld | Not as easily weldable and fabricable as austenitic grades | Requires heat treatment for optimal properties |

Austenitic Stainless Steels

The predominant and arguably most crucial stainless steel type is austenitic stainless steel. This category is characterized by a high chromium and nickel content, delivering reliable corrosion resistance and excellent mechanical properties. While it can’t undergo hardening through heat treatment, austenitic stainless steel is favored for its capacity for hardening through cold-working.

These steels are easily workable and weldable, exhibiting excellent ductility, toughness, corrosion resistance, and good strength. This stainless steel class is often further categorized into low-carbon (designated by “L”) with carbon levels below 0.3% and high-carbon (“H”) with carbon levels between 0.4% and 1%. With chromium content ranging from 17 to 25% and nickel content from 8 to 20%, they may contain additional elements for desired properties, commonly molybdenum, to enhance corrosion resistance.

Austenitic stainless steels are typically used in the annealed condition, providing a useful range of mechanical and physical properties. While non-magnetic in the annealed state, austenitic stainless steels may become slightly magnetic after cold working.

Types of Austenitic Stainless Steel

- Grade 303: It is a non-magnetic stainless steel alloy, highly machinable, and commonly used in heavily machined parts. It has corrosion-resistant properties but less so than 304 stainless steel. It is not recommended for water use or welding.

- Grade 304: This stainless steel has a tensile strength of 621 MPa. It is versatile and widely used. It has high resistance to temperature and corrosion, making it ideal for various applications.

- Grade 304L: It is a low-carbon variant of 304. It maintains corrosion resistance but is less prone to sensitization during welding. Suitable for thicker parts not post-weld annealed, with a temperature limit of 425ºC.

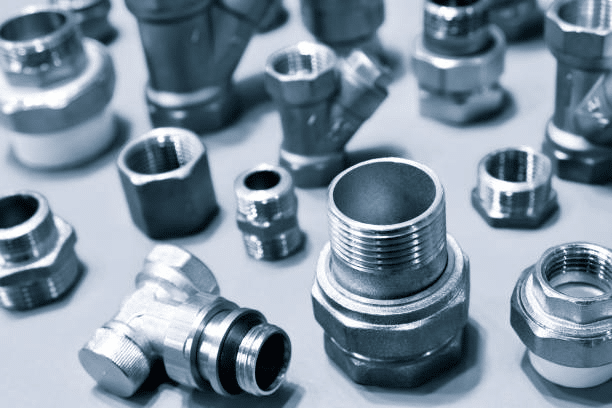

- Grade 316: This type is known as the marine alloy. It offers high tensile strength and improved corrosion resistance with added molybdenum. Preferred for applications exposed to chlorides.

- Grade 316L: It is the low-carbon variant of 316 stainless steel. It shares similar corrosion resistance but is less susceptible to sensitization during welding. Used for thicker parts not post-weld annealed, with a temperature limit of 425ºC.

- Grade 317: Similar to other austenitic stainless steels, it has high corrosion resistance and tensile strength. The addition of molybdenum enhances resistance to chloride-induced pitting, suitable for chemical processing and marine industries.

- Grade 321: With added titanium, it withstands corrosion from chemicals and high temperatures. It is non-magnetic, can resist oxidation up to 1500 degrees Fahrenheit, and has higher stress rupture properties than grade 304.

Ferritic Stainless Steels

Following austenitic, ferritic stainless steel stands out as one of the most popular and widely used classes of stainless steel. This type is created by incorporating alloy elements such as aluminum, molybdenum, or titanium. This is in addition to the nickel and chromium found in austenitic material. Chromium levels dictate corrosion resistance, and specific grades may include additional molybdenum.

Ferritic stainless steels share comparable strength, ductility, and fabrication characteristics with carbon steels but offer superior corrosion resistance. With chromium content ranging from 10.5% to 22%, these steels lack the nickel addition in austenitic grades. They are also known for their resistance to stress, oxidation, and corrosion.

Ferritic stainless steels exhibit relatively poor high-temperature strength, limiting their applicability in various contexts. They are generally unsuitable for welding due to grain growth in the heat-affected zone. They are usually used in the annealed condition and are consistently magnetic under all conditions. Their ability to maintain strength under stress makes them particularly suitable for automotive applications, including exhaust systems, shafts, axles, and fasteners.

Types of Ferritic Stainless Steel

- Grade 405: This stainless steel is suitable for mildly corrosive environments, with lower corrosion resistance than grade 430. It doesn’t harden after welding, making it useful for steam nozzles and quenching racks.

- Grade 409: It is a utility stainless steel with approximately 10.5% chromium. 409 is primarily used in automotive exhaust systems. However, the surface stains and metal loss is slower than with carbon steel.

- Grade 420: This is the hardest among stainless steels at 50 HRC with 12% chromium. It offers good ductility and corrosion resistance. Commonly used in cutlery, it resists bases, fresh water, and mild acids, but prolonged exposure to certain foods may cause pitting.

- Grade 430: It is the most common ferritic stainless steel, suitable for mild indoor environments, automotive trim, and dishwasher liners. With 17% chromium, its corrosion resistance is slightly less than grade 304 SS.

- Grade 434: This stainless steel grade is a stronger alternative to 430. It has a tensile strength of 540 MPa. It is better for high-temperature applications than 316 stainless and has excellent pitting resistance compared to 430.

- Grade 436: A modification of 434, including columbium and molybdenum, to reduce roping during stretch forming. It is highly magnetic and resistant to abrasions. Machinists use it in appliance trims and automotive applications.

Martensitic Stainless Steels

These stainless steel types stand out as a crucial steel class widely used in handheld items. It is a great choice when products require robust strength with less emphasis on corrosion resistance. This type of stainless steel is characterized by its magnetic properties and typically excludes the use of nickel. This group comprises 12% to 16% chromium and 0.08% to 2.00% carbon, allowing effective heat treatment to achieve high mechanical strength and hardness.

They are distinguished by a higher carbon percentage, often around 1%. While magnetic and capable of hardening with heat, it is not the most corrosion-resistant option compared to austenitic and ferritic steel. However, welding these grades can be challenging due to the detrimental effects of high carbon content. Limited ductility and resistance to cold working are characteristic of martensitic stainless steels.

Martensitic grades remain magnetic under all conditions. Martensitic steel finds diverse applications, particularly in smaller handheld items where corrosion is a secondary concern. Common uses include surgical instruments, cutlery, heater parts, springs, wrenches, furnace components, etc.

Types of Martensitic Stainless Steel

- Grade 410: It is a general-purpose stainless steel with 12.5% chromium, suitable for mildly corrosive environments. This stainless steel is inexpensive for general purposes, like cutlery, bolts, and furnace parts. It is also suitable for high-strength applications like chutes and screens.

- Grade 410S: 410S is a low-carbon variant of grade 410. It remains non-hardening at high temperatures, preventing cracking during welding. This grade is commonly used in petroleum refining, thermal processing, and petrochemical industry applications.

- Grade 414: It is essentially grade 410 with added nickel, making it stronger at similar thicknesses. Used for mining equipment like spindles & shafts, fasteners, beater bars, and valve seats.

- Grade 416: This stainless steel grade boasts the highest machinability among stainless steels. It is available in various forms and has less corrosion resistance than austenitic steels. However, it is highly resistant to acids, alkalis, and fresh water. Used in components like gears, bolts, and washing machine parts.

- Grade 420: Annealed 420 stainless steel has a tensile strength of around 586 MPa, increasing to 1,586 MPa when hardened and stress relieved. While not as chemically resistant as other stainless steels, it has good resistance to mild acids, water, some alkalis, and food compounds. It is commonly used for applications when impact resistance and tensile strength are crucial.

Duplex Stainless Steels

They combine ferritic and austenitic steel, resulting in a material with an equal mixture of the two types, offering a range of useful properties for this class. Comprising equal parts of austenite and ferrite, duplex stainless steels contain 18 to 29% chromium, 3 to 8% nickel, and various elements like molybdenum and nitrogen. They offer advantages over austenitic grades, increasing strength with double or more yield strength.

They also boast a high resistance to chloride stress corrosion cracking. The higher alloyed grades exhibit excellent resistance to pitting and crevice corrosion. Duplex grades are not heat-treatable, have a low response to cold work, and are typically used in the annealed condition. They are weldable and fabricable, though not as easily as austenitic grades, and remain magnetic under all conditions.

The robust yield strength makes it crucial for sheet metal fabrication, manufacturing, and structural purposes. When appropriately employed, its strength and anti-corrosion properties make it a cost-effective resource. This material finds application in storing or transporting chemicals. It is employed in pressure vessels, desalination plants, heat exchangers, marine applications, construction, etc.

Types of Duplex Stainless Steel

- Grade 2205: It is a duplex stainless steel with 22% chromium, 5% nickel, and 3% molybdenum. Its high alloy content provides superior pitting and crevice corrosion resistance, and the duplex structure offers excellent stress corrosion cracking resistance. Known for high strength, it is well-suited for use in high chloride environments, such as heat exchangers and chemical industry equipment.

- Grade 2304: With corrosion resistance similar to grade 316, this grade boasts nearly double the yield strength. It performs well in colder temperatures within the range of -58°F to 572°F, making it suitable for various applications.

- Grade 2507: A duplex stainless steel featuring high thermal conductivity, corrosion resistance, and a low coefficient of thermal expansion. It is ideal for applications requiring excellent corrosion resistance and strong tensile strength. Manufacturers use this grade in marine and petrochemical equipment and various mechanical and structural components.

- Grade S32750: This super duplex stainless steel grade contains 25% chromium, 7% nickel, and 4% molybdenum. It offers the highest resistance to pitting and crevice corrosion among duplex grades. It also exhibits increased resistance to stress corrosion cracking and very high strength. Applications include oil and gas industries, petrochemical plants, and components requiring high strength and corrosion resistance.

Precipitation-Hardening Stainless Steels

This group comprises 12% to 16% chromium and 3% to 9% nickel. It also contains small additions of precipitate-forming elements like copper, aluminum, titanium, and niobium. These metals share qualities with both martensitic and austenitic stainless steel. Stronger than martensitic stainless steel, they possess corrosion resistance matching austenitic metals.

Designed to be heat-treatable for very high strength, they offer better ductility than martensitic grades. They are typically machined and fabricated in the soft, solution-annealed condition. After this, they are then tempered to achieve the desired combination of ductility, strength, and toughness.

PH stainless steels are commonly utilized in high-tech industries such as aerospace, nuclear, and chemical applications. They also find applications in boat shafting.

Types of Precipitation Hardening Stainless Steel

- Grade 17-4: This precipitation-hardening stainless steel is known for exceptional strength and moderate corrosion resistance. Its strength can be adjusted through heat treatment and exhibits fair machinability and magnetic properties. This grade is widely used in aerospace, petroleum, and chemical industries.

- Grade 15-5: It offers high strength, ductility, corrosion resistance, transverse toughness, and hardness capabilities. While not ideal for cold working, it is suitable for hot working. This precipitation-hardening stainless steel is commonly used in high-pressure, corrosive environments and is suitable for aerospace parts.

How To Determine the Suitable Stainless Steel Type for Your Project

The following factors will help you decide the right stainless steel grade for your unique project.

Formability and Weldability

For applications needing good formability, consider selecting an austenitic or ferritic stainless steel, like grades 304 or 430. Remember that martensitic steel, like grade 410, is weaker and prone to cracking. Additionally, consider the weldability of the stainless steel if you intend to weld it to another metal.

Corrosion Resistance

Due to their elevated chromium content, austenitic stainless steels are suitable for challenging environments. Grade 316, in particular, provides the highest level of corrosion resistance among austenitic steels. More economical options like martensitic stainless steel and ferritic stainless steel can also be viable choices in corrosive settings.

Application Environment

The stainless steel you select should match the demands of the operating environment. Opt for a grade with the required strength, toughness, and resilience to endure the specific pH levels, temperatures, stressors, and corrosion.

Strength, Toughness, and Ductility

Consider the weight your application must support, its required ability to change shape without compromising strength, and the conditions that could lead to steel fracture. Stainless steel alloys incorporating chromium and nickel offer an optimal blend of strength, ductility, and toughness for such considerations.

Availability and Cost

Austenitic stainless steels tend to be costlier but commonly represent the highest quality steel options. Despite the initial cost, you might discover long-term savings on maintenance and repairs due to the superior quality of these stainless steels.

Conclusion

Stainless steel offers corrosion and heat resistance in addition to the standard properties of steel. It encompasses steel’s benefits while adding its advantages of enduring harsh environments and boasting an extended service life. With numerous types of stainless steel grades featuring distinct properties, there’s always an ideal grade for specific applications. Choosing the right grade is crucial for a cost-effective investment and outstanding results.

Depending on your application, consulting with an experienced manufacturing company is recommended. In this case, Zintilon is your best bet. Our engineers offer top-notch expertise to consider the various factors influencing design needs. We ensure you get the delivery of the optimal stainless steel solution for the best results. Get a quote now for your custom manufacturing services.