In today’s production, the CNC machine is indispensable. It allows a faster pace of new product releases and promotes operational effectiveness. This article will discuss how CNC machining is revolutionizing modern manufacturing practice.

This design of the CNC machine helps in reducing the manufacturing lead times. It boosts production, reduces cost, and ensures quality with excellent outcomes. CNC technology is applicable for many purposes such as mass production and prototyping. It provides efficiency in machining operations.

What is the role of a CNC machine in increasing overall productivity and scale? What is its role in reducing waste in production processes? Join us and let’s explore extensively these problems, give appropriate recommendations while bearing in mind how far and how much influence this apparatus has been instrumental to modern industry.

What is CNC Machining?

Several production and design processes of many industries are being transformed by “Computer Numerical Control”, or CNC machining. This is an organized procedure involving collaboration between various machine tools together with automated controls for removing a workpiece made of metal, including CNC machine metal. This leads to made-to fit components which are designed to address particular concerns.): Surprisingly, the use of this technology is not confined within one area. This is flexible enough to accommodate automotive, aerospace, construction and agriculture. Ponder that precision in constructing automobile frames, medical apparatuses, aircraft engines, gear mechanisms, and even backyard equipment.

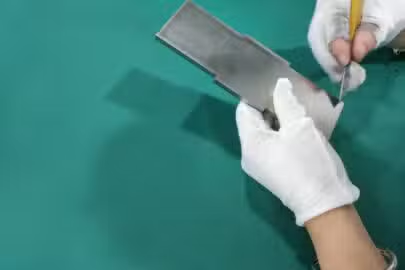

It is so magical because of the computer software used in CNC machining. This is systematically programmed in advance, it is used to regulate and direct the motions of machines and other tools in industries. Modern technology governs everything right down from mills to routers, lathes, and grinders. AI Written Such a concept takes us to a place where machines are so automated that bits of a milling machine, wires of an EDM machine and cutting heads of a lathe would be moved by a computer. This degree of automation is astounding. It makes it possible to create complex parts with precise measurements. This ability is essential in sectors like aerospace, automotive, and medicine, where precision is essential.

Nevertheless, CNC machining has some other benefits. It is revolutionary in respect to automation. This is because it allows manufacture of parts of varying complexity. All these kinds of material like composite, foam, wood, plastic and metals are handled by CNC machines. Flexibility ensures that manufacturers and suppliers of CNC machining services can offer wide ranges of clients’ requests.

Furthermore, there are unmatched benefits toCNC machining services:

- Ability to Handle Production-Grade Materials: CNC machines can be used in many industries due to their ability to process most available materials including metals and composites.

- Maintain Repeatability and Accuracy: Every aspect of the CNC machined parts meets specific quality criteria thanks to its high precision.

- Respect Strict Tolerances: CNC machining allows for accurate product production especially in areas that require precision or zero-tolerance.

- Fast Turnaround: CNC machining promotes quick product turnarounds with some of the short periods of a day.

These benefits are underscored by emphasizing these through CNC cutting processes. These advantages consist of using production grade materials, strict tolerance, repeatability and accuracy as well as fast response time.

How CNC Machining Speeds Time to Market

On the other hand, CNC machining leads to shorter lead-time, uses lesser skills, and fast iteration and modifications. Faster process of new product development. With time, this leads to a beneficial effect on machining manufacturers and their clients.

Faster Iterations and Revisions

Another remarkable feature of a CNC machine is that it can facilitate quick design adjustments as well as fast prototyping. As you may assume, CNC machines can produce parts within a single day.ҽ This allows manufacturers to test, adjust, and design with ease. This fast turnaround enables one to identify and address any design issues or improvements within a short period making the time it takes to develop a new product ready for the market considerably shorter.

Shorter Lead Times

Another critical advantage of CNC machining is its substantial lead time reduction. CNC machining allows production of different manufactured components with a high level of accuracy by making the production process automatic through usage of computerized control systems and machines. It also provides for operation of machines at full tilt and re-calibration of cycle time using the IoT devices thus smoothening the production workflow. This efficacy ensures shorter lead times between the designs and the final product as speed in the market matters.

Less Reliance on Skilled Labor

Lastly, CNC machining eliminates the demand on high-skill personnel fabricating complex products. Compared to manual production, CNC requires less physical and mental work effort since it is pre-programmed. The homogeneity ensures a smooth, exact, and consistent outcome with minimal reliance on human capability. It enhances speed, efficiency and trustworthy production outputs by simplifying the process through addressing the issue of skills scarcity.

How CNC Improves Efficiency

By using the process of CNC machining,, the company is able to make things easy in terms of efficiency due to the automated, consistent, little use of material waste, as well as the ability to create complex components. Also, automation, reduction of wastes, processing of complicated components, and increase of production operations are also included.

Automation and Consistency

One of the advantages of CNC machining is its automation potential. The pre-programmed software that each CNC machine uses guarantees its accuracy for each part it produces. Compared with manual operations, which may be inconsistent, CNC machining provides remarkable consistency. This enhances faster and better production of parts that are good quality. This leads to general boosted productivity of CNC machining companies and machine manufacturers as a whole.

Less Material Waste

Now let’s talk about waste, or lack of it. However, when it comes specifically to CNC machining it’s so precise that less of the material gets wasted. This is because CNC machines are designed to cut in the most efficient way possible hence making sure that raw materials are utilized more effectively. As a result, it decreases expenses and enables CNC machining to be a more eco-friendly and green process. The sustainability and affordability nature of this feature of CNC machining makes it very attractive for industries with such priority agenda.

Ability to Machine Complex Parts

The ultimate power of CNC machines can only be realized in the final case where complicated items are involved. You often find these machines with tough tolerances that can be difficult if not impossible to achieve using the traditional methods. The ability here is quite groundbreaking especially in those settings involving the presence of intricate parts such as aviation goods and medical equipment. The precision and high quality of CNC machine produced parts greatly expedite and improve product quality.

Industries Benefiting from CNC Machining

CNC machining goes beyond mere manufactures and touches on many vital sectors in our society. It is the center of many economic sectors, like aerospace, the making of medical devices, and the automobile industry.

Aerospace Manufacturing

Aircraft production would be impossible without the use of CNC machining. Think of what it takes to manufacture things such as satellites, spaceships, and planes. All of them are very precise and reliable. These levels of precision, uniformity, and agility can be achieved in CNC machining. It makes complex pieces like control surfaces, engines and structural parts. It is because in the aviation industry, the precision associated with CNC machining influences the performance and safety of aeronautical vehicles CNC technology isn’t simply helpful. Vital to the aerospace industry.

Medical Device Manufacturing

In relation to medicine, CNC machining also comes in handy. The precision, flexibility in use as well as being among the bedrock of medical device production today makes CNC machining a key building block. In the dynamic context of the present time medical industry environment production of crucial parts, for example, orthopedic implants and surgical products as well as prototyping of electronic housings, among other things, requires CNC machinization.

On many occasions, the road from concept to reality in medical devices begins with prototypes. This is where CNC machining comes in, offering a fast and economical solution to prototype manufacture of medical devices. This helps engineers quickly evaluate and make necessary modifications on their final design to meet the requirements of safety, efficacy, and regulation for the final product before reaching the mass production stage.

Secondly, CNC machining has a huge effect on the manufacturing of orthopedic implants like the hip replacements and knee implants. In terms of strengths, the procedure gives designers freedom to make complex models accommodating titanium and stainless steel, the most well-known biocompatible materials. This skill makes CNC machining important in production of these vital medical appliances.

Additionally, CNC machining is not limited to the production of implants and surgical instruments but also involves the manufacture of housing and casing for medical devices and equipment. Technology must also be able to create complex geometries with close tolerances, as this influences the reliability and function of electronic components in medical devices. This application focuses on the large but well-developed medical devices manufacturing industry where the CNC technology makes its contribution.

Automotive Manufacturing

CNC machining does not leave the high ways either. CNC machining is popularly used by the auto industry to produce many parts comprising, for instance, engine blocks, gearbox compartments, brake discs, suspensions, and illuminations. CNC machining has many advantages for the automotive industry, e.g. tighter tolerance of parts, reproducibility, resemblance, higher production speed, and effectiveness.

Complex part production with close tolerances can be done by CNC machining including engine blocks and gearbox components. Precision and accuracy in the production of the parts using cnc machining help to enhance the quality and reliability of the automotive components.

The other advantage of CNC machining is that it can produce prototype models that will serve as working models during testing and validations before undertaking bulk production. Due to that, design problems are resolved and corrected at a higher speed leading to the shortened “time to market” of auto items.

Below is an overview of the best benefits and products made possible by this great technology in the aerospace, medicine and automotive manufacturing sectors.

| Industry | Benefits of CNC Machining | Key Components Produced |

| Aerospace Manufacturing | Precision, consistency, and speed | Control surfaces, engines, and structural components |

| Medical Device Manufacturing | Precision, ability to handle specialized materials, high-quality finishes | Surgical implants, medical tools, and orthotic devices |

| Automotive Manufacturing | Reliability, accuracy, and efficiency in complex designs | Engine blocks, gearbox parts, brake discs, and suspension components |

Conclusion

To end with, CNC machining redefines modern production hence speeding up of product development lifecycle and enhancing efficiency. Moreover, CNC machines act as great enablers through automation, shortened cycles of iterations, and lesser dependencies of skilled people. This offers vast market opportunities in sectors such as aerospace, medical devices, and automotive manufacturing. Sustainability, speed, and precision are critical with CNC machining. Would you like to get more out of yourself? You should use CNC machining today.