The modern automotive industry weighs heavily on innovation and automation, which has led to an increase in reliance on a manufacturing process like CNC machining, dubbed automotive CNC machining. Its wide acceptance by many automakers is due to its speed and cost-effectiveness in making custom and high-quality auto parts.

CNC automotive machining supports rapid prototyping and manufacturing of many auto parts. However, successful production depends on understanding the process. As a result, this article discusses CNC machining and its application in the automotive part manufacturing industry.

What is Automotive CNC Machining?

Automotive CNC machining comprises a series of CNC machining techniques applicable to the automotive industry. In short, it uses the CNC machining process for automotive parts. CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove part of a workpiece and form the right product.

Common Automotive CNC Machining Techniques

CNC car parts machining often consists of several single or combined techniques to produce several auto parts. Each has a unique way of function and is suitable for different auto parts. Below are the common techniques used by many a CNC auto service.

CNC Turning

CNC turning is a technique that involves rotating the workpiece on a lathe mounted with a cutting tool. The cutting tool removes part of the workpiece to create a product with either an external or internal cylindrical shape. CNC turning is a common CNC automotive operation in making parts such as crankshafts and camshafts due to the need for precision and accuracy.

CNC Milling

CNC milling is a more common CNC automotive operation that involves using a rotary cutting tool mounted on an automotive CNC machine to remove part of a workpiece. The machines can mill complex parts with common CNC auto parts made using the process being engine blocks, cylinder heads, and brackets.

CNC Drilling

CNC drilling uses a drill to create holes of different sizes and depths in some automotive parts. Examples of CNC car parts made using CNC drilling are brake discs and engine block mounting holes.

CNC Tapping

Tapping is used to make threaded holes on a part and is suitable for parts that require fasteners like bolt and nut and screws. Examples of CNC auto parts made using tapping are engine blocks and transmission casings.

CNC Grinding

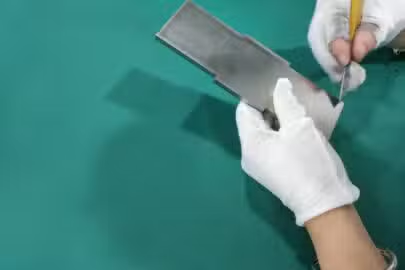

This involves using an abrasive wheel to remove part of a workpiece and it is suitable for auto parts that require tight tolerances and a smooth surface finish.

Common CNC car parts made using the process are camshafts, crankshafts, and precision bearings.

CNC Boring

Boring a machining technique for refining existing holes in order to improve the accuracy or enable proper alignment and fitment of auto parts during automotive assembly.

Examples of parts made using the process are the cylinder bores in engine blocks and transmission housings.

Advantages of Automotive CNC Machining

CNC machining is a popular manufacturing process in the automotive industry as manufacturers seek to enjoy its speed, repeatability, automation, and other benefits listed below:

Production speed

CNC machining enables rapid production cycle in medium and high volume production leading to a reduced lead time compared to traditional machining processes.

Automation

CNC machining is built on automation leading to high production speed and accuracy. Furthermore, there are lesser worries about human errores during the manufacturing process.

Repeatability

CNC machines precision guarantees consistency of a part having different batches which is important in the automotive part manufacturing industry since they make a many parts.

Accuracy

CNC car parts machining high accuracy makes it suitable for making part with tight tolerance or complex design common to the automotive industry.

Customization

Like 3D printing, you can also customize auto parts using CNC machining which reduces the lead times.

Common Material Used in the Automotive Industry

Several materials are used to make different automotive components. Each has its properties and aesthetic value and is chosen based on performance, safety, and aesthetic value. Here are the common materials in the industry.

Steel

Steel is a strong, durable, and impact resistant material for making auto parts exposed to high loads. You can use different steel grades to make structural components like the car chassis, engine blocks, and transmission gears.

Aluminum

Aluminum is a lightweight and corrosion resistant material with good thermal conductivity applicable in making CNC auto parts like engine blocks, cylinder heads, and wheels.

Polypropylene

Polypropylene is lightweight, chemical-resistant, impact-resistant, low-cost thermoplastic suitable for manufacturing interior automotive parts like door panels.

Polyethylene

Polyethylene is lightweight, flexible, chemical resistant, and impact resistant. Common auto parts made using the material are fuel tanks and exterior trim components.

Acrylonitrile Butadiene Styrene

ABS is a tough, moldable, impact-resistant thermoplastic with good dimensional stability and heat resistance. It is applicable in making interior trim components such as door handles and vents.

Polyurethane

Polyurethane is a durable automotive CNC thermoset polymer known for its impact and weather resistance. As a result, it is applicable in making outdoor automotive parts such as bumpers and body panels.

Polyethylene Terephthalate

PET is a lightweight, dimensionally stable, and moisture resistant material with high clarity and application in making headlight lenses, housings, etc.

Polycarbonate

Polycarbonate is a transparent, heat-resistant, and impact-resistant thermoplastic used in making automotive lighting such as headlight lenses and sunroof panels.

Nylon (Polyamide)

Nylon has incredible strength, durability, abrasion resistance, and low coefficient of friction which makes it suitable for making components like gears, bushings, and bearings.

Fiberglass

Fiberglass is strong, lightweight and corrosion resistant for making structural auto parts like body panels. However, it is difficult to machine and expensive.

Copper

Copper has a heat and electricity conductivity. Hence its use in making auto parts that require efficient energy transfer and thermal management such as radiators and heat exchangers.

Magnesium

Magnesium has a high strength-to-weight ratio that makes it suitable for making part that reduces the overall vehicle weight. These include transmission cases, steering wheels, and other lightweight automotive structural components.

Common Surface Treatment Used in the Automotive Industry

CNC machined parts have tool marks, sharp edges, burrs, and other forms of imperfections. As a result, some surface finish treatments are used to correct the imperfection. Furthermore, they are suitable for improving the functional properties of the parts, such as corrosion resistance.

Annealing

Annealing is a surface treatment option for CNC auto parts made from aluminum, copper, and brass. It involves heating the parts to a temperature high but not lower than its melting point. This leads to recrystallization, and on controlled cooling, the metal parts’ mechanical properties, such as strength and elasticity, increase.

Tempering

Tempering is another surface treatment method for reducing the hardness of a metal auto part. The part is heated to a temperature below the critical point according to the level of hardness to be reduced and the metal. At high temperatures, elasticity and plasticity increase while hardness and tensile strength reduce. On the other hand, at low temperatures, brittleness reduces without affecting the hardness.

Bead Blasting

Bead blasting is suitable for removing imperfections on the surface of auto parts. It occurs in a closed chamber and involves spraying the part with a pressurized stream of tiny plastic or glass beads. Consequently, the part has a smooth finish with a uniform satin finish. Bead blasting is a preliminary surface finish option for painting and anodizing.

Electroless nickel plating

This is suitable for improving the corrosion resistance of an auto part made from aluminum and steel. It involves depositing an even layer of nickel-phosphorus alloy on the part and dipping it into a water solution containing nickel salts and phosphorus-reducing agents.

The uniform deposition of the nickel-phosphorus is an advantage over electroplating and is responsible for its popularity in the automotive industry.

Powder coating

Powder coating is suitable for plastics and metal auto parts. It involves electrostatically coating the substrate using free-flowing dry powder and curing under heat or UV light. It is suitable for parts made from thermoplastic or thermoset polymers and metals such as aluminum and steel.

Anodizing

In automotive CNC machining, anodizing helps improve the oxide layer thickness, hence a better surface corrosion process.

It involves dipping the auto part in an acidic solution as an anode and an inert material as the cathode. Oxygen flows to the anode, passing electricity through the solution, forming the anodic oxide.

This ensures the part has improved corrosion resistance and leaves a coarse and grainy surface finish on the part. Furthermore, you can dye the part as the oxide layer can trap the dye and give a near-permanent color.

Galvanization

Also known as zinc coating or hot-dip galvanizing, galvanization involves coating metal auto parts using a zinc or zinc-iron layer. It is common among steel auto parts and provides corrosion resistance due to the uniform thick layer. Hot dip galvanization’s disadvantage is that exposure to the zinc layer can compromise the layer.

5 Axis CNC Machining Service in Automotive CNC Machining

Continuous advancement in the automotive industry has led to the popularity of 5-axis automotive CNC machines. 5-axis CNC machining is a multiple-axis manufacturing process that can achieve the complex needs of the automotive part manufacturing industry.

5-axis CNC machining allows the cutting tool to move along five axes instead of the three axes in the 3-axis CNC machine. The spindle can move up and down, side to side, back and forth, like the conventional 3-axis machine, but also include another movement. One is the table rocking side to side on two axes, and the other is the spindle swiveling on two axes.

These movements allow the cutting tool to approach the workpiece at high angles and create highly complex shapes peculiar to the automotive industry. Furthermore, there is a reduction in the complexity and number of setups needed. So, incorporating this in the automotive part manufacturing process can make the entire machining process faster.

Outstanding Custom Automotive CNC Machining Service at ZTL

CNC automotive machining has transformed the industry by enabling a precise, accurate, and repeatable manufacturing process. You can gain the best from the process by outsourcing to a reputable CNC machining service

At Zintilon, we render quality CNC machining services using advanced machining techniques and tools. We deliver rapid prototyping and manufacturing solutions for your parts with the utmost quality and precision.

Conclusion

CNC machining is known for its speed and accuracy and this article discussed the process so businesses can make the right decision on a manufacturing process for their products. You need a reputable CNC machining service and at Zintilon, we are a trustworthy and reliable CNC machining service provider. Contact us today.

FAQ

Can a CNC machine make car parts?

Yes, CNC machines can make many automotive parts with common ones being the transmission parts, engine components, and suspension components.

What does CNC stand for in automotive?

CNC stands for “Computer Numerical Control” which also means that the cutting tool is controlled by computer programs and numerical control systems..