Over the years, CNC machines have become widely used in various manufacturing industries. These machines automate tasks like cutting, drilling, milling, and turning, all thanks to computer numerical control (CNC) technology. With CNC machines, manufacturers can create intricate designs and parts with remarkable accuracy and precision.

There are different types of CNC machines, the most common one being 3-axis CNC machines. One of its key strengths lies in its ability to create detailed designs and parts with high accuracy. The 3-axis CNC machine is a cutting-edge device.

This article focuses on how well 3-axis CNC machines can handle cutting slanted angles and curved shapes, which are crucial for many manufacturing projects. You will also know everything about 3-axis CNC machines and their versatility. By exploring the capabilities of 3-axis CNC machines in these areas, you can better understand their usefulness across different industries.

Defining the 3-Axis CNC Machine

Understanding the Basics

A 3-axis CNC machine is a remarkable feat of modern manufacturing, offering both precision and versatility. But what exactly does “3-axis” mean? It’s quite simple, really—it refers to the machine’s ability to move in three directions: side to side (X-axis), front to back (Y-axis), and up and down (Z-axis). This three-way movement allows the machine to work on a piece from different angles, making it incredibly versatile for various fabrication tasks.

Core Components of a 3-Axis CNC Machine

X, Y, and Z axes:

- The X-axis moves the cutting tool horizontally, going from left to right.

- The Y-axis controls the tool’s movement forward and backward, adding depth to cuts.

- The Z-axis manages the vertical movement, adjusting the tool’s height as needed.

Cutting Tool:

- At the heart of every 3-axis CNC machine is the cutting tool.

- This tool, which includes drills and mills, is responsible for shaping the material.

Worktable:

- The worktable acts as the machine’s base, securely holding the material in place.

- It can move along the X and Y axes, ensuring precise positioning of the workpiece.

Controller:

- Acting as the machine’s brain, the controller interprets the design specifications.

- It then converts these instructions into precise movements for the machine to execute.

Spindle:

- The spindle houses the cutting tool and rotates at various speeds.

- The spindle’s speed and direction play a crucial role in the cutting process.

Drive Motors:

- These motors are the powerhouse of the machine, moving the axes according to the controller’s commands.

- Their accuracy and strength determine how precisely and quickly the machine operates.

The Basic Function of a 3-Axis CNC Machine

The X, Y, and Z-axis movements form the backbone of a 3-axis CNC machine’s functionality. Together, they orchestrate a symphony of precise movements, bringing intricate designs and shapes to life with high accuracy and efficiency. Whether it’s woodworking, metalworking, or plastic fabrication, the versatility of these movements unlocks a world of creative possibilities. Here is their basic functionality:

X-Axis Movement

The X-axis movement in a 3-axis CNC machine is akin to its side-to-side motion. Picture the cutting tool gliding horizontally, smoothly shifting from left to right along a precise path. This movement allows the tool to make accurate cuts across the material’s width. In woodworking, for instance, the X-axis movement can craft clean edges on a wooden board or carve intricate designs with meticulous detail.

Y-Axis Movement

Next, we delve into the Y-axis movement, where the tool moves forward and backward. Imagine the cutting tool advancing and retracting along the length of the material, much like a gentle push and pull. This movement adds depth to the cuts, enabling the machine to sculpt the material with varying thicknesses. For metalworking applications, the Y-axis movement can create grooves, slots, or precisely drilled holes in metal pieces.

Z-Axis Movement

Lastly, we explore the Z-axis movement, which is responsible for the tool’s up-and-down motion. Imagine the cutting tool adjusting its height, smoothly lowering or raising itself in relation to the material’s surface. This pivotal movement controls the depth of the cuts, allowing the machine to create intricate contours and shapes. In plastic fabrication, for example, the Z-axis movement can sculpt 3D models with seamless curves and precise angles.

Here’s a table summarizing the Benefits of 3-axis CNC Machining:

| Benefit | Description |

| Versatility | 3-axis CNC machines are versatile and can work with a wide range of materials, from metals to plastics and composites. They can produce various part geometries. |

| Precision | These machines offer high precision, achieving tight tolerances and accurate cuts consistently. |

| Efficiency | 3-axis CNC machining improves efficiency by automating processes, reducing manual labor, and minimizing material wastage. |

| Cost-Effectiveness | Compared to higher-axis machines, 3-axis CNC machines are often more affordable to purchase and operate. |

| Ease of Programming | Programming for 3-axis machining is relatively straightforward, making it accessible to operators with basic training. |

Limitations of Basic 3-Axis Motion

Even though 3-axis CNC machines boast remarkable versatility and precision, they do have limitations due to their fundamental motion capabilities. Here are the limitations:

Lack of rotational movement

A major limitation of basic 3-axis motion is the absence of rotational movement. While the cutting tool can move in the X, Y, and Z directions, it cannot rotate as it cuts. This means that creating complex shapes requiring smooth curves or rounded edges becomes challenging. For instance, crafting intricate sculptures or parts with curved contours may pose difficulties without additional axes of rotation.

Limited Access to Complex Surfaces

Another challenge arises from the machine’s inability to access all areas of a complex surface. Imagine an object with intricate details on all sides. The fixed axes of a basic 3-axis CNC machine restrict its reach, making it tough to reach certain areas for machining. This limitation often necessitates multiple setups or manual adjustments to complete the machining process fully.

Difficulty with Undercuts and Overhangs

The basic 3-axis motion also struggles with machining undercuts and overhangs on a workpiece. These features require the cutting tool to reach beneath the surface or over an edge to create the desired shape. Without the ability to tilt or pivot the tool, the machine finds it challenging to access these areas effectively. Consequently, producing complex parts with undercuts or overhangs may demand multiple setups or specialized tooling.

Increased machining time and tool wear

Due to these limitations, machining intricate parts on a 3-axis CNC machine can take longer and lead to increased tool wear. The machine often requires additional operations, tool changes, or repositioning to achieve the desired geometry. This extended process can result in longer production times, elevated costs, and more frequent replacements of cutting tools.

Challenges in Multi-Sided Machining

When machining a workpiece from multiple sides to achieve complex geometries, a 3-axis CNC machine faces challenges. Each side of the part requires a new setup and precise alignment. This increases the chances of errors and inconsistencies between surfaces. Achieving accurate alignment and matching geometries across different sides can be time-intensive and may demand advanced CNC programming expertise.

Advanced Techniques for 3D Machining

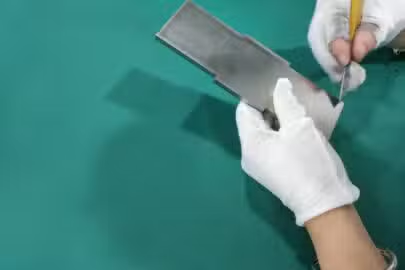

Demonstrating the versatility of 3-axis CNC machining, the machine is shown cutting a complex curved shape into a piece of wood.

Advanced techniques for 3D machining, such as tilting the workpiece and contouring with interpolated motion, open doors to a world of intricate designs and precise geometries. These methods offer manufacturers the ability to create complex parts and components with unmatched precision and efficiency, pushing the boundaries of what is achievable with 3-axis CNC machines. Here is a more detailed explanation of the advanced techniques for 3D machining:

Tilting the Workpiece

One advanced technique in 3-axis CNC machining involves tilting the workpiece itself to access different angles and contours. By tilting the workpiece, manufacturers can create complex 3D shapes that would otherwise be challenging with basic 3-axis motion.

Benefits:

- Enhanced Accessibility: Tilting the workpiece allows the cutting tool to reach areas that would be difficult or impossible to access with traditional motion.

- Smooth Curves and Angles: This technique enables the creation of smooth curves, intricate angles, and complex geometries with precision.

- Reduction of Setup Time: Instead of repositioning the entire machine, tilting the workpiece reduces the need for multiple setups, saving time and effort.

Contouring with Interpolated Motion

Another advanced technique is contouring with interpolated motion, where the machine smoothly follows a defined path to create intricate shapes and designs.

How It Works:

- The CNC machine uses interpolated motion to move the cutting tool along a predefined path.

- This path can include curves, arcs, and complex shapes, all achieved with precise control.

Benefits of Advanced 3D Machining Techniques

- Enhanced Precision: These advanced techniques offer unparalleled precision in creating complex 3D shapes and surfaces.

- Expanded Design Possibilities: Manufacturers can explore intricate designs and geometric shapes with ease.

- Improved Efficiency: Reduced setup times and optimized tool paths lead to faster production and lower costs.

- Versatility: From aerospace components to artistic sculptures, these techniques cater to a wide range of industries and applications.

Applications of 3-Axis Machining Techniques

The applications of 3-axis machining techniques are vast and varied, playing a crucial role in industries ranging from aerospace to automotive, medical, electronics, and beyond. Here are some of the key applications:

Precision Engineering in Aerospace:

In the aerospace industry, where accuracy and dependability are key, 3-axis CNC machines are vital. Aircraft and spacecraft parts often need precise shapes and close fits. These can include main parts, engine pieces, supports, and complicated covers. 3-axis CNC machines are great for making these parts from materials like aluminum, titanium, and composites. Whether it’s making mounts for avionics or cutting turbine blades, the precision, and adaptability of 3-axis milling machines ensure that crucial aerospace parts meet strict quality rules.

Automotive Manufacturing:

Car making relies a lot on 3-axis machining for making many parts. From motor bits to car body covers, forms, and shapes, CNC machines are important for building. For example, in making tools and shapes, 3-axis machining is used to make molds and shapes for pressing, making stamps, and forming processes. Also, the ability to work with different materials helps makers to produce both strong and good-looking parts efficiently. Whether it’s shaping motor blocks or creating detailed designs for car dashboard parts, 3-axis milling machines guarantee high precision and repeating patterns in car making.

Medical Device Making:

In the medical field, where customizing and accuracy are important, 3-axis machining is crucial. Medical toolmakers depend on CNC machines to make implants, fake body parts, surgery tools, and detailed parts for checking gear. These parts often need materials that work well in the body, like titanium, stainless steel, or special medical plastics. Whether it’s making a special bone piece or creating detailed parts for small surgery tools, 3-axis machining lets makers create top-quality, exact medical tools that meet the exact needs of patients and health pros.

Electronics:

The electronics industry gets help from the exactness and adaptability of 3-axis machining for making special covers, heat takers, connectors, and other parts. Whether it’s making detailed covers for phones or creating exact parts for everyday electronics, CNC machines give the exactness and speed needed for big production. Also, the ability to work with different stuff, like metals and strong plastics, makes 3-axis machining good for lots of electronic jobs.

Architectural sector:

Outside of usual manufacturing jobs, 3-axis machining is used in the art and building fields. Building planners and artists use CNC machines to make detailed designs, art pieces, and models. Whether it’s making pretty parts for buildings or making big art pieces, 3-axis CNC machining lets artists and planners create their visions with exactness and speed. The ability to work with many stuff, like wood, metal, and rock, lets for endless creative ideas in building and art jobs.

The Future Prospects of 3-Axis CNC Machines

The Future Of 3-Axis CNC Machining Technology

The future of 3-axis CNC machining technology holds exciting possibilities and is set to transform manufacturing processes across various industries. Looking ahead, several significant developments are shaping 3-axis CNC machines.

Enhanced Automation:

Future 3-axis CNC machines will become more automated, integrating advanced robotics and AI systems. This advancement will streamline production processes, reduce the need for manual labor, and greatly improve overall efficiency.

Smart Manufacturing:

The integration of Internet of Things (IoT) technologies will enable real-time monitoring and analysis of CNC machine performance. This will lead to optimized operations, predictive maintenance, and better production planning.

Advanced Materials Processing:

Evolving 3-axis CNC machines will be capable of handling a wider array of materials, including advanced composites, ceramics, and exotic alloys. This expansion will create opportunities for new applications in industries such as the aerospace, automotive, and medical sectors.

Precision and accuracy:

Ongoing advancements in spindle technology, tooling, and control systems will result in even higher levels of precision and accuracy in machining operations. This will empower manufacturers to create increasingly intricate and sophisticated parts.

Emerging Trends in CNC Machining

Several emerging trends are on the horizon, poised to shape the future of CNC machining with innovative approaches and capabilities.

Additive and Subtractive Integration:

The fusion of additive manufacturing (3D printing) with subtractive CNC machining will give rise to hybrid systems. This integration will facilitate rapid prototyping, intricate part fabrication, and enhanced design flexibility.

Multi-Tasking Machines:

Future 3-axis CNC machines will possess multitasking capabilities, consolidating milling, turning, and grinding operations into a single setup. This integration will lead to reduced production times and increased productivity.

Adaptive Machining:

Adaptive machining techniques, guided by real-time sensor data and AI algorithms, will optimize tool paths and cutting parameters dynamically. This will result in improved surface finishes, reduced tool wear, and heightened energy efficiency.

Energy Efficiency and Sustainability:

With a growing emphasis on sustainability, forthcoming CNC machines will feature energy-efficient designs and environmentally friendly practices. This includes optimizing cutting parameters to minimize waste and energy consumption.

Conclusion

The exploration of 3-axis CNC machines uncovers precise and efficient manufacturing. These machines, known for their ability to craft complex designs and top-notch mechanical parts, stand as cornerstones of engineering innovation. While they excel at tasks such as straight cuts and curved surfaces, it’s crucial to recognize their limitations, particularly when dealing with complex shapes.

Understanding what 3-axis machining can do, as well as its limitations, helps manufacturers choose the best process for their needs. For deeper insights into the machining world, consider contacting us at Zintilon. And discover more about our wide range of machining solutions and services.

FAQs

Can 3-axis CNC machines cut slant angles?

Yes, 3-axis CNC machines can cut slant angles. They can tilt and move the cutting tool to create angled cuts on materials.

How accurate are 3-axis CNC machines?

3-axis CNC machines are known for their precision. They can achieve tight tolerances and create detailed designs accurately.

What factors should be considered in designing for 3-axis CNC machining?

When designing for 3-axis CNC machining, factors like tool access, material constraints, and part orientation are important. Designers aim to optimize the process for efficiency and quality.