Optimizing supply chain management is vital to pursue performance and competitiveness in nowadays’s dynamic commercial enterprise surroundings. Companies that need to succeed apprehend the importance of innovation in simplifying approaches, decreasing expenses, and ensuring timely transport of excessive satisfaction Among these wishes Computer Accounting (CNC) machining operations emerge as a transformative force, offering blessings that deviate from subculture for manufacturing methods

CNC machining services are driven via precision and through today’s generation and are emerging as an important thing of modern production. CNC machining has helped redesign the production and supply chain, from extraordinary precision in production to enabling faster prototyping and manufacturing techniques

In this comprehensive guide we will go over the application of CNC machines, revealing each aspect of its application and the essential strategies to improve the supply chain.

Background on CNC Machining Services

CNC machining has emerged as a cornerstone in the ever-changing production enterprise. It is converting the way products are designed and assembled. Understanding these tasks offers us an appreciation in their impact on modern-day production. Here we will supply an explanation for the CNC machining packages, sorts, and capacity advantage of the use of CNC machining applications.

What Are CNC Machining Services?

CNC machining services is a contemporary technique of making products and parts and with an immoderate stage of precision. CNC stands for Computer Numerical Control, which means computer systems are important in guiding and controlling the machining equipment. Unlike conventional techniques that depend upon manual operation, CNC machining makes use of automated procedures based totally on virtual designs.

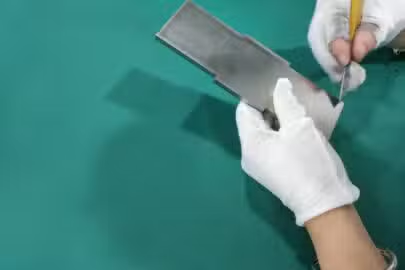

Imagine an automated machine guiding a device to form raw materials, like steel or plastic, into unique additives. This manner allows for the creation of hard and complicated additives with constant notable. CNC machining services cover quite a range of strategies, such as turning, milling, and electrical discharge machining (EDM), every serving specific manufacturing needs.

The key takeaway is that CNC machining offerings leverage advanced generation to make production more efficient, accurate, and flexible. This era has come to be a cornerstone in current manufacturing, offering a dependable and automated method to generate top-notch additives for numerous industries.

Types of CNC Machining Services

Here are several types of precision CNC machining services:

CNC Milling

In milling, a revolving tool makes bodily touch with the workpiece to cut and dispose of chips. Numerous activities, which include threading, slotting, and chamfering, are finished with this technology. With simply one milling center, it is able to produce intricate and complex designs.

With tolerances as tight as /- zero.1 mm, CNC milling offers exceptional accuracy. This CNC machining carrier consists of several sub-types, consisting of Face, Form, Gear, Profile, and Surface milling packages. Subtypes can mill in three methods: axially, laterally, or hybridally.

Various metals (titanum, aluminum, chrome steel) and plastics (polycarbonate, nylon, POM, HDPE, ABS, and many others.) may be processed using milling.

CNC Turning or Lathing

CNC turning, known as CNC lathing, makes cylindrical additives along with bushings or shafts. The CNC moves the reducing tool to and from and axially alongside the facet even as the metal component spins.

The preferred diameter and form are achieved by using eliminating the cloth surrounding the metallic’s circumference. CNC machines with sliding heads or constant heads may be used for turning. The latter is applied to reduce down on manufacturing time and final costs.

CNC Drilling

This CNC machining provider mainly creates cylindrical holes in a workpiece the use of multi-point drill bits. This approach can drill each perpendicular and angular holes. While perpendicular drilling is as easy as placing a rotating drill bit into a workpiece using a CNC gadget, angular drilling may be slightly more complicated.

Clamping devices and specialised machined configurations are wanted for angular drilling. CNC Drilling may be used for various operations, such as tapping, reaming, and countersinking.

Wire EDM Machining

Wire EDM is also called wire EDM cutting, wire cutting, EDM cutting, twine-cut EDM, wire burning, twine eroding, wire erosion, wire cut electric powered discharge machining, or even ‘cheese-cutter’ EDM.

In wire electrical discharge machining (WEDM), a skinny steel wire is used to cut or shape a workpiece, normally made of conductive cloth. The cord follows a carefully programmed path to create the favored shape. The diameter of the electrode wire normally ranges from .004″ to .012″ (.10mm to .30mm), with alternatives for smaller or large diameters.

What’s specific about cord EDM is that there is no contact among the wire and the workpiece throughout the reducing process. This permits for machining without causing any distortion inside the twine’s direction or the shape of the fabric being labored on.

To gain this, the wire is swiftly charged to a specific voltage and is surrounded via deionized water. When the voltage hits the right level, a spark jumps the distance, melting a small a part of the workpiece. The deionized water then cools and flushes away the tiny particles created inside the hole.

5-Axis CNC Machining

This machining technique uses a device that acts in five guidelines even as rotating. It’s a manner of making matters using slicing away materials, and the gadget shapes the cloth in 5 guidelines: up, down, sideways, and rotating in two methods.

These movements are referred to as X, Y, Z, A, and B. With 5-axis CNC machining, the system can simultaneously work on a component from all sides and angles. This approach there’s no want to transport the piece round manually between steps. It saves time and works well for making complex components with splendid accuracy.

Benefits of Using CNC Machining Services

Here are some of the benefits of using CNC machining services:

Faster Assembly

Products crafted using computer numerical control (CNC) exhibit a streamlined assembly process. The precision and consistency of CNC machining ensure that companion parts fit together exactly as designed.

Unlike manual machining, the CNC process is faster, reducing the time spent waiting for parts. Given the accuracy of CNC machining, assembly requires minimal fitting and adjustment, resulting in significant time and cost savings.

Energy Efficiency

CNC machining stands out for its reduced energy consumption compared to older methods. According to the EPA, CNC machining uses only about one-seventh energy consumed by traditional machining techniques.

This efficiency is attributed to the quick operation of CNC machines, which draw less power per minute than many other manufacturing methods.

Effective and Rapid Production

A key gain of CNC machining is its inherent velocity and performance in manufacturing. Modern CNC machines can produce items hastily and autonomously, from loading the plain fabric to unloading the finished product without human intervention.

This degree of automation leads to giant value savings and guarantees greater consistency in the produced components.

Precision and Accuracy

A fundamental advantage of CNC machining is its unprecedented accuracy. Computer-managed commands manual CNC machines, ensuing in equal and intently matching outcomes with the computer model. This precision is mainly positive when developing elements with tight tolerances, actually doing away with human blunders from the producing procedure.

Reduces Wastage

Beyond efficiency, CNC machining minimizes cloth wastage owing to its precision. Proper design within the computer interprets into the machine making few if any, defective cuts. This precision permits the gadget to deal with difficult cuts and angles with minimal waste, developing a extra sustainable and aid-efficient manufacturing system.

Low Production Cost

CNC machining emerges as an economical, green, and particular approach for production components and products. In comparison to standard machining, CNC generation utilizes fewer raw materials. Shifting to CNC technology reduces mistakes and lowers manufacturing expenditures and typical product prices, making it a value-effective answer for modern-day manufacturing.

10 Ways CNC Machining Services Enhance Supply Chains

Here are the top ten ways in which using CNC services can boost your supply chains:

Faster Turnaround Times

CNC machining’s contribution to faster turnaround instances is rooted in its automated and pre pregrammed processes. Unlike conventional manufacturing methods that frequently require guide adjustments and setups, CNC machines function with precision based totally on pre-programmed instructions. This automation reduces the time it takes to install and execute responsibilities, leading to quicker manufacturing cycles. Moreover, the non-stop and uninterrupted operation of CNC machines similarly hastens the production system.

This extended speed is treasured for industries wherein fast production is essential, allowing them to satisfy deadlines and reply promptly to fluctuations in market.

Flexibility and Agility

The flexibility of CNC machining arises from its programmable nature. Manufacturers can without difficulty reprogram CNC machines to accommodate layout changes or adjustments. This adaptability is important in industries in which product designs evolve swiftly, or customization is crucial.

Traditional manufacturing techniques, which can also involve creating new molds or gear for design changes, often result in tremendous delays. CNC machining lets in for swift changes, making it possible to respond to evolving marketplace trends or purchaser preferences with minimum downtime.

Low Volume Production

CNC machining is ideal for successfully managing low-volume production runs. Traditional techniques like die casting or injection molding, can be price-prohibitive or time-consuming when coping with small batches of parts. CNC machining, on the other hand, eliminates the want for pricey tooling adjustments and setups related to mass production methods.

This makes it economically viable to produce confined quantities of elements, making CNC machining a great solution for businesses handling niche markets, speedy prototyping, or the ones requiring on-call for manufacturing without the weight of maintaining massive inventories. Quickly switching among designs makes CNC machining suitable for producing numerous merchandise in small quantities.

Design and Engineering Support

CNC machining services often offer comprehensive design and engineering guide to clients. Experienced specialists can collaborate with layout groups to optimize product designs for manufacturability the use of CNC tactics. This aid includes remarks on fabric choice, tolerances, and capacity design improvements.

Integrating Computer-Aided Design (CAD) with CNC machining allows a continuing transition from conceptualization to production. This collaboration permits that the final product meets design specs and is optimized for efficient and fee-effective manufacturing.

Advanced Capabilities and Technology

CNC machining leverages superior abilties and generation to deliver precision and performance in production. Using multi-axis machining, pre-programmed movements, and high-pace cutting tools allows for producing complex and complex parts with tight tolerances.

Additionally, incorporating cutting-edge CNC machines and software program enhances typical production performance. The persistent advancement of CNC era guarantees that producers can live at the leading edge of innovation, producing high-quality components with stepped forward velocity and accuracy.

Quality and Consistency

CNC machining is renowned for its capacity to supply regular and top notch results. The precision carried out via laptop-controlled tactics eliminates the variety associated with guide operations. This consistency is important for maintaining product pleasant throughout large manufacturing runs.

Quality manipulate measures, along with in-technique monitoring and inspection, make sure that each element meets stringent first-class standards. The reliability of CNC machining contributes to the overall integrity and popularity of the final products.

Inventory and Cost Reduction

CNC machining plays an essential function in cost and inventory reduction techniques. The ability to supply components on demand and in particular quantities minimizes the need for large inventory stockpiles. Traditional manufacturing strategies frequently require bulk production to justify setup costs, main to extra stock and associated preserving prices.

CNC machining’s efficiency in handling low-quantity manufacturing permits companies to lessen inventory tiers, minimizing the danger of overproduction and related prices. This leaner technique of manufacturing aligns with present-day supply chain concepts, optimizing resource utilization.

Prototyping and New Product Introduction

CNC machining plays an essential role within the prototyping segment of product improvement. Its potential to fast and correctly produce prototypes permits producers to test and validate designs earlier than committing to full-scale manufacturing. CNC machines can create prototypes with the equal precision because the very last product, supplying a suitable representation for checking out and evaluation.

This iterative method to prototyping facilitates perceive design flaws, refine specs, and in the long run reduce the threat of mistakes in the very last product. CNC machining’s speed and accuracy make it an invaluable device inside the early levels of latest product introduction.

Direct-to-End-Use Part Production

CNC machining isn’t only suitable for prototyping but also for the direct production of end-use components. The precision and repeatability of CNC tactics make sure that the final elements meet the favored specs consistently. This functionality is particularly fantastic in industries in which small to medium production portions of notably custom-designed or specialized parts are wanted.

CNC machining allows an extra streamlined and value-effective transition from layout to quit-use manufacturing with the aid of bypassing the want for tooling changes and setups related to conventional production techniques.

Focus Internal Resources on Core Competencies

Outsourcing CNC machining services allows organizations to focus their internal sources on middle abilities. Instead of investing in and coping with the complexities of keeping an in-house CNC machining facility, businesses can leverage the expertise of external CNC machining service vendors.

This outsourcing strategy allows agencies to concentrate on their core strengths, which includes product design, marketing, and normal commercial enterprise approach. By entrusting CNC machining to specialized provider companies, corporations can beautify performance, reduce operational burdens, and strategically allocate resources.

Choose Zintilon to Improve Your Supply Chains with CNC Machining Services

Choosing Zintilon for your CNC machining services is a strategic pass towards improving the performance and precision of your supply chains. Renowned for precision engineering, Zintilon utilizes advanced CNC machining capabilities that guarantee the correct production of components, contributing to the general excellence of your supply chain.

Beyond precision, Zintilon guarantees time performance with modern-day machinery and streamlined approaches, lowering manufacturing times and facilitating faster turnaround instances.

The flexibility presented in production runs and collaborative layout optimization makes Zintilon an agile partner that seamlessly aligns with your production desires. Cost-powerful answers without compromising pleasant, dependable high-quality control measures, and a steadfast dedication to well-timed project delivery in addition solidify Zintilon as a reliable organization in elevating the overall performance and performance of your delivery chains.

With Zintilon, you gain a CNC machining provider and a relied-on partner dedicated to optimizing your delivery chain methods. Contact us now!

Conclusion

The importance of incorporating CNC machining services into your supply chain is obvious. It’s like including a secret component that modifies the complete recipe. CNC machining brings a new wave of efficiency and accuracy. It’s the ability to quick tweak designs or the cost-effectiveness of handling smaller production runs.

Zintilon’s collaborative approach and commitment to timelines make bigger these blessings. By imposing these ten techniques, you are not only upgrading your production but also future-proofing your supply chain for the demands of tomorrow’s market. As industries evolve, integrate CNC machining for a supply chain that keeps up and leads the way. Get a quote today to begin!

Read More

- Aluminum Die Casting: Benefits, Applications, and Design Tips – Zintilon

- Choosing the Right Milling Machine: A Comprehensive Guide to Horizontal Milling vs. Vertical Milling – Zintilon

- Rapid Tooling: Process, Advantages, and Application – Zintilon

- The Difference Between Brass, Bronze and Copper – What Sets Them Apart – Zintilon

- Navigating the Landscape of Digital Manufacturing – Zintilon