Annealing is a heat treatment method applicable in making metals more ductile and machinable. As a result, it is a common surface-finishing process in automotive, manufacturing, tool and die production, and other industries.

A mistake in any step of the annealing process can lead to irreversible damage. As a result, part manufacturers must understand the annealing process. This article is a quick guide to annealing, introducing the process, its benefits, and applications.

What is Annealing?

Annealing is a process that involves heating a part to a high temperature until recrystallization occurs. The high temperature weakens the metallic bond. As a result, the atoms move faster and further apart.

As cooling occurs, the time moves closer and recrystallizes. This gives room for further cold working. Furthermore, the annealing process alters the metal’s microstructure as the lattice structure becomes strain-free after the heat treatment.

Why is Annealing Important?

Annealing is a crucial step in manufacturing because of the following.

- It alters the metal’s physical properties and sometimes the chemical properties. For example, it increases the metal’s ductility and strength while reducing hardness. Hence, the annealed metals are more formable and easy to work on.

- Annealing is a cost-effective way to improve a metal’s electrical and corrosion resistance properties.

- Additionally, annealing enhances wear resistance and amplifies magnetic properties. This makes this process ideal in the production of motors and transformer components.

The Different Types of Annealing

There are four basic types of annealing each with a unique mechanism to achieve different results:

Full Annealing

Full annealing involves heating metal like softened medium and high carbon steel above the critical temperature. The metal is heated to about 50 degrees past its austenitic temperature, left at that temperature for some time, and then cooled

A temperature rise will ensure an even distribution of the alloying elements. Note that full annealing is time-consuming and energy-intensive due to the need to control the cooling phase to prevent excessive grain growth.

Stress Relief Annealing

Annealing aims to release a metal’s residual stresses which can be due to plastic deformation, phase transformation, or non-uniform cooling. Stress relief annealing comes after different manufacturing processes that cause changes to the tiny grains of materials.

This technique involves heating the metal at a low temperature, usually 550 degrees and 650 degrees for gray cast iron and steel respectively. Note that one cannot eliminate residual stress. You can only reduce it to the barest minimum.

Process Annealing

Process annealing or subcritical annealing is a good option for treating low-carbon steel. You carry out this technique below the Ac1 temperature for an extended time. For steel, the required temperature is between 260 and 760 degrees.

Because of the reduced temperature, this type of annealing process does not involve the formation of austenite. Instead, it ensures a uniform distribution of spheroidal carbides.

Solution Annealing

Solution annealing involves heating at a temperature where the metal turns into a solid solution. This process is useful when dissolving formed precipitates in stainless steel. The resulting product transforms into a single-phase structure.

Unlike other annealing processes that require a slow cooling rate, solution-annealed materials must undergo rapid quenching to room temperature. Rapid cooling will prevent the occurrence of precipitation as it seals in the single-phase solution.

The Benefits of Annealed Metal

Annealing a metal has several benefits which make the process common in the part manufacturing industry. Below are some of the advantages of using annealing to treat metal parts.

Improved Ductility

Manufacturers anneal metals mostly to enhance ductility i.e., to allow them to stretch into tiny threads or wires without rupturing. Pulling an unannealed metal leads to breakage without distorting.

Enhanced Machinability

Annealing makes it easy to machine metal parts. You can cut them into different shapes and sizes. Furthermore, annealing produces parts with a better surface finish without deformation. This technique boosts production efficiency and prolongs tool life.

Increased Weldability

The annealing process increases the ease of joining of metals using heat and pressure. It prevents the build-up of stress as the weld solidifies. The welded joints are clean, strong, and are less likely to crack. Furthermore, annealing makes dissimilar material welding faster and defect-free.

Removes Internal Stress

A key importance of annealing is to relieve residual stress from a material. This makes annealing essential for parts prone to fatigue or fracture. Removing internal stress makes deformation uniform along the metal’s length.

Applications of Annealed Metal

Annealing is a versatile process suitable for metals like stainless steel, cast iron, aluminum, and magnesium. Common applications of annealed metal include:

Automotive Industry

Annealing is an important process in the automotive industry used in the manufacturing of parts like gears, axle shafts, and brake systems. Furthermore, the annealing process improves the durability of exterior auto parts like chassis, steering, and suspension.

Construction

Annealed metals are used in making hydraulic cylinders, crankshafts, blades, and pistons used in the construction industry. Furthermore, annealing is also used in improving the properties of metals used in making bridges and other construction. This heat treatment will ensure that the joints are strong and aesthetically pleasing.

Aerospace Industry

Many aerospace components rely on stress reduction to function maximally. As a result, annealing reduces the risk of dimensional changes in turbine blades, engine stator rings, gears, and transmission parts.

Tool and Die Production

Annealed metals used in tool and die production have a longer lifespan. Furthermore, they are accurate and repeatable due to wear resistance and their ability to retain their shape under high-stress conditions.

Electrical Industry

Annealing is common in the electrical industry when working with aluminum and carbon. It makes them less brittle and ductile and enhances their electrical conductivity. Consequently, they can perform optimally and conduct a large amount of electrical current efficiently.

The Annealing Process Step-by-Step

Regardless of the type of annealing, there are four basic steps. Let’s look at each step in detail.

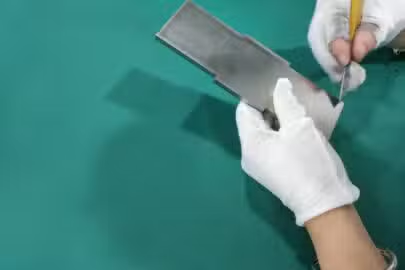

Preparation of the metal

The first step in annealing is adequate preparation of the metal parts. Clean off any grease, or dirt that can interfere with the process. You do this by brushing and using alkaline cleaners. Additionally, remove impurities such as rust or scale from the metal surface.

Heating

After preparing the metal, slowly heat the metal at a predetermined temperature depending on the metal in question. For example, annealing aluminum occurs at 300°C to 550°C. During this heating stage, ensure that the heat transfer is uniform. Evenly heated metal prevents misshaping and cracking.

Soaking Temperature and Time

The next step is to hold the metal at the appropriate temperature until the metal’s internal structure changes. The soaking time varies and usually depends on the metal’s mass. One can also carry out a chemical analysis to determine the holding time. Note that for parts with varying thicknesses, the largest section takes priority when determining the appropriate time.

Controlled Cooling

The final step in annealing is controlled cooling. You cannot use the metal parts if they are not at room temperature. Cool them using solid, liquid, or gaseous medium. The cooling medium used depends on the size and properties of the metal.

Zintilon Support for Your Custom Die Casting Service

High-pressure die casting compatibility with different materials and parts with complex designs makes it a top option for many manufacturers. However, its high initial cost can impede choosing it which makes considering a die casting service a better option.

At Zintilon, we have the manufacturing capability to manufacture high-quality die casting parts. We are quality-focused and offer you a competitive price. Contact us and enjoy a fast lead time and competitive market pricing.

Conclusion

Annealing is important in metal manufacturing as it softens the metal and improves properties such as ductility, wear resistance, and electrical and mechanical properties. It is important to understand the process, and to choose the right thermal conditions. We hope this article answers your questions on metal annealing. Feel free to contact us for further questions and clarifications.